Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Enzymatic sulfation helps solve lignin’s solubility problem

Adding sulfate groups to phenols improves the recalcitrant material’s solubility in water and should aid production of aromatic compounds

by Stephen K. Ritter

May 8, 2017

| A version of this story appeared in

Volume 95, Issue 19

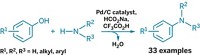

Lignin produced by plants is nature’s greatest source of aromatic compounds, and it’s readily available as a by-product of the pulp and paper industry. It seems natural that chemists would want to take advantage of the material as a source of aromatics to reduce reliance on coal, oil, and natural gas. One problem is that lignin’s aromatics are locked up in complex insoluble polymeric chains. Gadi Rothenberg, Ron Wever, and coworkers of the University of Amsterdam have developed an enzymatic process to selectively add hydrophilic sulfate groups to lignin’s many phenol rings to make the material easier to dissolve for processing (ChemSusChem 2017, DOI: 10.1002/cssc.201700376). Wever’s group previously found that a bacterial aryl sulfotransferase enzyme can take sulfate groups from p-nitrophenylsulfate and add them to hydroxyl groups of various phenol compounds. The joint team has now extended the chemistry to various types of lignins. The researchers show that the process is selective for phenolic groups, leaving aliphatic hydroxyl groups in lignin side chains untouched. The resulting sulfated lignins dissolve easily in mildly alkaline solutions, with the increase in solubility visible to the naked eye and traceable by UV-Vis and NMR spectroscopy. The researchers note that the new method improves on prior lignin sulfating processes as well as current approaches that use caustic solutions, ionic liquids, or supercritical solvents, which are relatively costly and generate significant waste.

CORRECTION: The reaction scheme in this story was updated on May 19, 2017, to correct the sulfating agent structure. It was missing one oxygen in the sulfur group.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter