Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

New catalytic route to polysulfates and polysulfonates

Bifluoride salts could yield tough polymers efficiently at industrial scales

by Stu Borman

June 22, 2017

| A version of this story appeared in

Volume 95, Issue 26

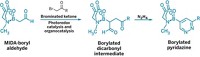

Polysulfates and polysulfonates are exceptionally tough and impact resistant, making them useful engineering polymers. But they’ve rarely been used industrially because the chloride substitution chemistry often used to make carbon sulfate and carbon sulfonate links suffers from side reactions and is commercially impractical.

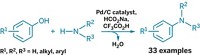

Researchers now report that bifluoride salts are efficient and cost-effective catalysts for the synthesis of these tough materials (Nat. Chem. 2017, DOI: 10.1038/nchem.2796). The new chemistry, developed by K. Barry Sharpless and Peng Wu of Scripps Research Institute California, Jiajia Dong of the Shanghai Institute of Organic Chemistry, and coworkers, could potentially be scaled up to industrial levels.

The new reaction is an extension of sulfur(VI) fluoride exchange (SuFEx), a click chemistry technique Sharpless and coworkers developed previously (Angew. Chem. Int. Ed. 2014, DOI: 10.1002/anie.201309399). The group initially used SuFEx, catalyzed by strongly basic “organosuperbases,” to combine silyl ethers with fluorosulfates or sulfonyl fluorides to form polysulfates or polysulfonates, respectively. But the catalysts were expensive or required high loadings, up to 10 mole %, and they reacted in unwanted ways with starting materials.

The team turned instead to acidic bifluoride catalysts—Q+[FHF]–, where Q+ is a wide range of organic and inorganic cations and the anion is a hydrogen trapped between two fluorines through a superstrong hydrogen bond. The new catalysts require tiny loadings—as low as 0.05 mole %—making the syntheses more commercially viable.

Polymer chemist Saadyah Averick of the Allegheny Health Network Neuroscience Institute comments that the catalysts also extend the substrate scope to a wider range of monomers. This chemistry makes polysulfates and polysulfonates more readily available, so “applications of these materials can be fully explored,” he says.

Two companies are negotiating with Scripps to license the technology.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter