Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Automating reaction discovery

Approach combines chemical design and informatics to find new chemical transformations

by Bethany Halford

July 17, 2017

| A version of this story appeared in

Volume 95, Issue 29

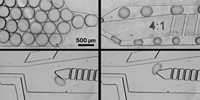

When hunting for novel chemical reactions, the more transformations chemists can do, the more likely they are to find something new. University of California, Berkeley, chemists John F. Hartwig and Konstantin Troshin have come up with an approach that lets reaction hunters run 75,000 possible reactions in just a matter of days using only a sealed 96-well plate, a gas chromatography/mass spectrometry instrument, and an analytical suite of Microsoft Excel macros (Science 2017, DOI: 10.1126/science.aan1568).

The reaction discovery method updates an earlier approach taken by Hartwig’s lab, in which the chemists loaded a combination of 17 reactants into each well of a 96-well plate and then added a different metal and ligand combination to each. They then used GC/MS to analyze their results (C&EN, Sept. 12, 2011, page 10).

“The deconvolution of the GC/MS data to identify more than the major products was a stumbling block for the routine use of this approach,” Hartwig says. So he and Troshin went back to the drawing board.

Their new method uses three pools of compounds. Each pool has molecules with the same types of functional groups: an alkyne, a halide, and a boronic acid, for example. The pools differ in that the compounds also have inert substituents that vary in mass. So when the compounds react, they form products with unique differences in mass that are detected by GC/MS and identified by analysis with the macros.

“By following these macros, the outcomes of thousands of possible reactions of two or multiple reactants can be analyzed in an automated fashion, and new reactions can be discovered,” Hartwig says.

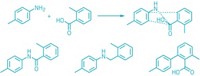

“This is a real breakthrough, since it speeds up the time for analysis and allows its automation,” comments Frank Glorius, an expert on smart screening at the University of Münster. He notes that Hartwig and Troshin even managed to use the method to discover a previously unknown nickel-catalyzed, three-component reaction (shown). “This paper will attract a lot of interest from chemists from different disciplines, leading to more activity in this challenging field of ‘smart screening,’ ” Glorius says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter