Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Tracking health with paper electronics

Smart watch trims cost using sticky note sensors and 3-D printing

by Matt Davenport

January 30, 2017

| A version of this story appeared in

Volume 95, Issue 5

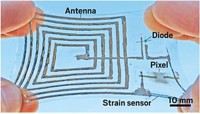

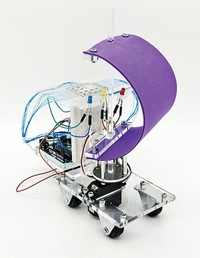

Muhammad M. Hussain and his team at King Abdullah University of Science & Technology are on a path paved with sticky notes and silicon to make wearable health trackers more affordable for everyone. Using sticky notes, silver ink, aluminum foil, and clean-room wipes, Hussain’s team created low-cost pressure, moisture, and temperature sensors connected to flexible silicon circuits for data handling and transmission. The team’s work has been accepted and will be published soon in Adv. Mater. Technol. By printing silver ink coils and capacitors on cellulose sticky note substrates, the team created simple temperature and moisture sensors, respectively. Changing temperatures are detected as changes in the ink’s electrical resistance, whereas the paper’s dielectric permittivity responds to moisture introduced by sweat, measurably altering the sensor’s electronic profile. To track a person’s pulse, the team built pressure sensors with clean-room wipes sandwiched between strips of aluminum foil. A wipe’s microfibers compress and relax along with the staccato blood flow through the wrist’s radial artery, causing the sandwich sensor’s capacitance to fluctuate with the heartbeat. Each sensor is mounted to a 3-D-printed wristband, resulting in a device that costs about $25 to make, the team reports.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter