Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Nanomaterials

Printing silver ink creates a spectrum of structural colors

Silver nanoparticles ink-jet printed on patterned polymer sheets could be a fast, cheap way to make security stamps for authenticating documents

by Jyoti Madhusoodanan

January 13, 2017

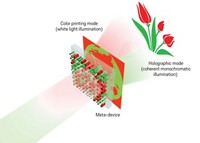

Ink containing silver nanoparticles is widely used to print flexible surfaces with electronic circuits, which turn out to be colorless. Now, researchers have found that printing this silver ink on a polymer sheet carrying nanoscale patterns can generate iridescent colors (ACS Nano 2016, DOI: 10.1021/acsnano.6b06531). The colorful polymer sheets could be used as security stamps to authenticate currency notes, passports, and other documents.

The colors come from the way silver deposited on the patterns interferes with specific wavelengths of light. These so-called structural colors—which depend on the physical shape of nanostructures—are more durable and fade-resistant than pigments. But methods used to make them—such as photolithography, thin-film deposition, or laser printing—are usually expensive and slow, making it difficult to produce patterns over larger surfaces.

Inkjet printing, however, is a fast, cheap way to deposit silver nanoparticle ink over large areas. Compared to other technologies, “inkjet printing is the simplest in terms of speed, cost, resolution, and other properties we can control such as brightness,” says lead study author Hao Jiang of Simon Fraser University.

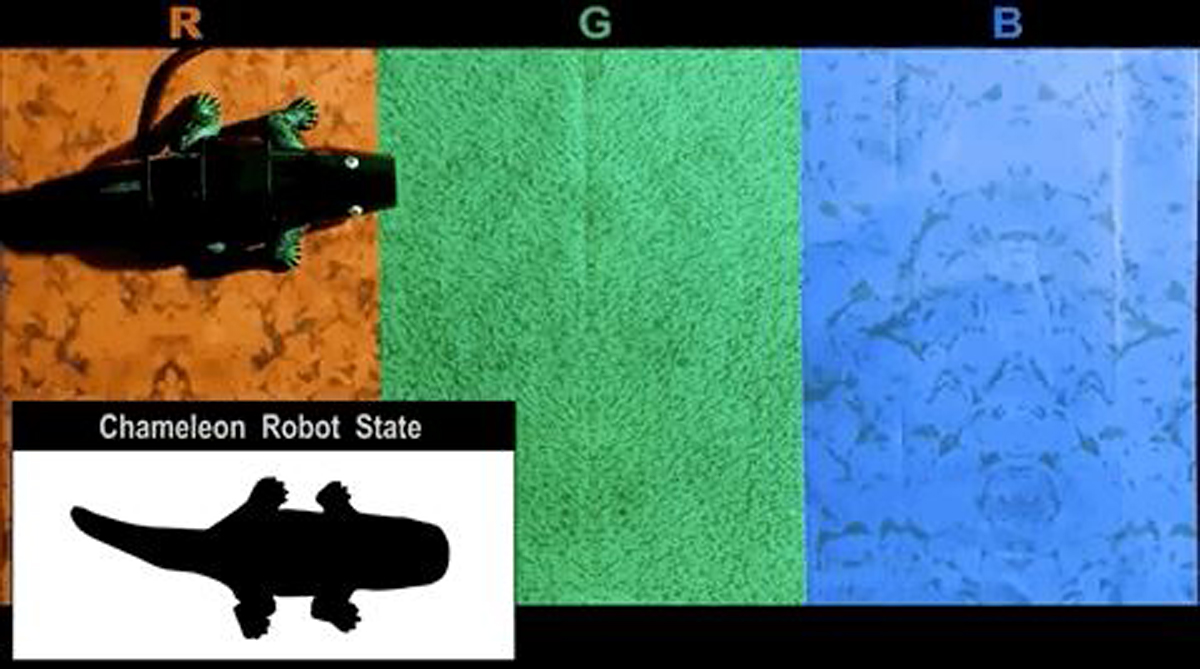

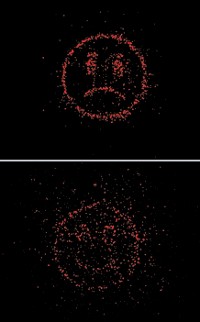

Jiang and his colleagues began by pressing a pattern of raised cone shapes—approximately 750 nm high and 520 nm wide at the base—into transparent sheets of plastic. Then, they used an ink-jet printer to cover the sheets with an alcohol-based ink carrying 50-nm-diameter silver nanoparticles, creating 100- to 300-nm-thick layers of silver on the polymer. Small differences in the cones’ shape and spacing resulted in red, green, or blue color.

Like with a computer screen, combining separate pixels of the three colors in different proportions produced a full spectrum of colors. The brightness can be varied by depositing more or fewer nanoparticles per pixel.

The resulting hues are strongly iridescent, changing depending on the angle from which they’re viewed. Such properties are particularly useful for making optical security markings for documents, Jiang says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter