Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Nanocomposites cut down on chromium waste from making leather

Treatment doesn’t sacrifice leather quality

by Carmen Drahl

March 5, 2018

| A version of this story appeared in

Volume 96, Issue 10

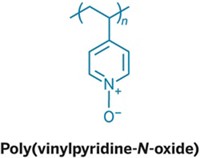

The cost of soft, supple leather shoes and handbags goes beyond the price tag. Chromium tanning agents transform roughly 90% of the world’s animal hides into leather, and a good deal of the chromium ends up in wastewater, where it becomes a hazard. To cut pollution levels, several groups have turned to nanocomposites, which improve chromium uptake into the network of polymerized collagen fibrils that makes up leather. Along those lines, Bin Lyu and Jianzhong Ma of China’s Key Laboratory of Leather Cleaner Production and colleagues now report that pretreating cowhide with vinyl polymer-zinc oxide nanocomposites before tanning improves chromium uptake in the resulting leather. The process also reduces chromium content in wastewater by 50 to 80% (ACS Sustainable Chem. Eng. 2018, DOI:10.1021/acssuschemeng.8b00233). Compared to conventionally tanned samples, the resulting shoe leather has similar durability and softness. Sujay Prabakar of New Zealand’s Leather and Shoe Research Association praised the work but would like to see techniques such as small-angle X-ray scattering employed in the future to learn more about the tanning mechanism and chromium uptake.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter