Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Spinning a triboelectric yarn

Material can be woven into textiles that harvest energy from motion

by Katherine Bourzac

January 8, 2018

| A version of this story appeared in

Volume 96, Issue 2

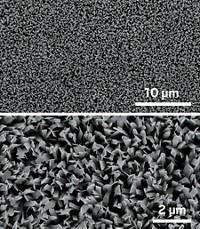

To Georgia Tech’s Zhong Lin Wang, our daily fidgeting, or even tossing and turning in bed at night, is a possible source of renewable energy. Wang’s group has made yarn composed of fabric fibers wrapped around a 50-µm-diameter stainless steel thread that can be woven into brightly colored, washable textiles that generate energy from motion (ACS Nano 2017, DOI: 10.1021/acsnano.7b07534). Sewn into clothing, the textiles could harvest enough energy from walking and everyday activities to charge cell phones and wearable electronics. The yarn is powered by the triboelectric effect, in which static electricity builds up from the friction between two different materials. When the materials move close together, electrons jump from one to the other. When they move back apart, those electrons flow into either a capacitor to store the charge or a circuit to generate power. As the yarn is stretched and released, the outer layer of fabric fibers—made from polyester, cotton, silk, or wool—moves closer to the stainless steel core, then away again, generating a small electric current. The researchers report that a sock with a textile patch charged a capacitor to 1 V after about 19 seconds of walking. The yarn works at up to 90% humidity, so it can survive heavy sweating. It also withstood 120 cycles through a washing machine, but it’s line dry only.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter