Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Pfizer automated flow system screens 1,500 reactions per day

Approach rapidly compares reaction outcomes for different reagents, conditions, and solvents

by Stu Borman

January 25, 2018

| A version of this story appeared in

Volume 96, Issue 5

Optimizing chemical reactions and finding the best ways to scale them up to produce compounds for clinical testing and drug commercialization can be tedious, time-consuming, and expensive.

To overcome these limitations, in 2015 Merck & Co. researchers developed a microtiter plate-based system in which reagents were pipetted at nanoliter volumes and then analyzed with liquid chromatography/mass spectrometry (LC/MS). The system carried out and evaluated nanomole-scale catalytic cross-coupling reactions at a rate of more than 1,500 per day (Science 2015, DOI: 10.1126/science.1259203). But that system requires the use of nonvolatile solvents that won’t evaporate easily from the open wells of microtiter plates, and reactions can’t be heated.

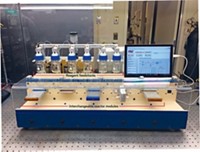

Inspired by the Merck system and advances in flow chemistry, researchers at Pfizer aimed to build an even more flexible high-throughput system for chemical reaction discovery. Damith Perera, Paul Richardson, Neal W. Sach, and colleagues at Pfizer now report having developed an automated instrument that can switch between volatile and nonvolatile solvents and can heat reactions to a variety of temperatures (Science 2018, DOI: 10.1126/science.aap9112). Importantly, the enclosed flow system alleviates the need for users to remake reagent solutions each time a new solvent is required.

To run a reaction, a user selects a so-called carrier solvent to flow through the system. This carrier solvent can be easily switched at any time. An autosampler injects into the flow 1-µL amounts of reactants, catalyst, and other reagents, each in a tiny amount of an appropriate solvent. These tiny amounts are only about 1% of the volume of carrier solvent in which they mix, so reactions occur in the carrier solvent alone, to a good approximation.

Flow systems typically use plugs of inert gases or fluorous solvents to separate reaction mixtures wending their way through the system’s tubing. The Pfizer system gains efficiency by eliminating these separators, since neighboring sets of reaction components don’t diffuse quickly enough to mix with each other during the reaction times, about 1.5 minutes each. Analysis time is slower than reaction time, so two LC/MS units switch off to match the flow output.

The researchers used the system to carry out and evaluate 5,760 Suzuki-Miyaura coupling reactions with different reagents and conditions at a rate of over 1,500 per day. “We don’t believe a single reaction has been more thoroughly pursued, particularly given the short time line of under four days,” Sach says.

“Translating miniaturized high-throughput methods to flow is sure to bring many advantages, such as the ability to heat and use diverse solvents,” says Tim Cernak of Merck Research Labs in Boston, one of the leaders of the 2015 Merck study. The Pfizer system necessitates full solubility of sample reactants and catalysts and high dilution as the 1-µL amounts mix into the comparatively high-volume flow , Cernak says, “so the grand challenge still remains for a miniaturized high-throughput technology that can use diverse solvents but still achieve greater than 0.1-M reaction concentrations, which many catalytic reactions require. Nevertheless, this is a really nice example of the interesting reactivity trends that can be visualized by systematically running thousands of reactions.”

Continuous-flow organic synthesis expert Wu Jie of the National University of Singapore notes that in its current form, the new system can’t evaluate heterogeneous processes such as gas-liquid or liquid-solid biphase reactions, but it’s a significant advance that “could save time and money for the drug industry.”

The Pfizer researchers hope to add capabilities to their system for photochemistry, heterogeneous reactions, and chiral analysis. They have no plans to commercialize the system but would like to see other scientists adopt it. “We actively encourage researchers to contact us to seek advice,” Sach says.

This article has been translated into Spanish by Divulgame.org and can be found here.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter