Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Process makes wood stronger than steel

Alkaline boiling and hot pressing collapse wood’s pores, maximizing its density

by Stu Borman

February 8, 2018

| A version of this story appeared in

Volume 96, Issue 7

Making strong materials like steel for construction, motor vehicles, airplanes, and thousands of other uses is an expensive and environmentally fraught process, requiring mining, huge factories, and lots of energy and producing pollution. Wood is a more readily available, less expensive, and more environmentally benign resource, and it is widely used to build homes and construct furniture. If wood also had the strength, impact resistance, and water resistance of steel, its applications could expand considerably.

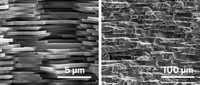

Researchers have tried to enhance wood’s properties in the past by treating it with steam, heat, or ammonia and then squashing—or densifying—it. But these treatments condense wood to about 40% of its original thickness at best, leaving some of wood’s internal pores and channels intact. And the resulting material still swells considerably when exposed to high humidity.

Teng Li and Liangbing Hu at the University of Maryland, College Park, have now devised a chemical and mechanical treatment for wood that eliminates its cavities and densifies it about twice as much (Nature 2018, DOI: 10.1038/nature25476).

The processed wood has higher specific strength (strength per unit density) than that of most structural metals and alloys and is a low-cost, high-performance, lightweight alternative to such materials, the researchers say. Li notes that “specific strength is a key design parameter in weight-sensitive applications, such as vehicles and aerospace applications.”

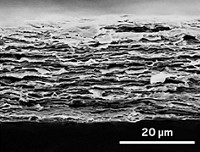

The researchers first boil natural wood in a solution of NaOH/Na2SO3 to make it more porous and less rigid. They then compress the treated wood perpendicular to its growth direction at 100 °C.

Wood has a preponderance of the glucose polysaccharide cellulose and lesser amounts of the mostly five-sugar polysaccharide hemicellulose and the phenolic polymer lignin. These components have different stabilities in the chemical bath, so the treatment removes nearly 75% of hemicellulose and 50% of lignin but leaves most cellulose intact. Partial lignin removal is key to compressing wood completely, the researchers found.

Hydrogen-bonding interactions between closely spaced cellulose nanofibers enhance the densified product’s strength. It gets slightly weaker and swells modestly in 95% relative humidity but becomes immune to moisture when given an oil-based coating. In a ballistics test, a 3-mm densified-wood laminate stops an air-gun projectile that glides easily through normal wood of the same thickness.

The University of Maryland spin-off company Inventwood will commercialize the technology, which has possible applications that include vehicle and boat bodies, shipping containers, armor, and flooring.

Li and Hu’s work shows that “enormous enhancement of mechanical properties of a natural material can be achieved by a relatively simple chemical-mechanical process,” says material mechanics expert Zhigang Suo of Harvard University.

Wood materials specialist Lauri Rautkari of Aalto University says he would like to know more about the densified wood’s response to direct water exposure and its load-carrying capacity, but he believes the study may represent a significant advance, saying he’s “super happy that this is being published.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter