After the birth of their daughter in 2017, the University of Alberta’s Serpe and his wife were faced with a torrent of baby furniture from Ikea. “It’s a pain in the ass to put together the stuff most of the time,” Serpe says. “You have to page through the manual, and I hate to read instructions.”

In a nursery littered with flat boxes, he had an idea: What if the furniture came with a small, self-folding replica made of plastic? Maybe, he thought, you could take a flat, plastic sheet out of the box and because it was impregnated with the humidity-responsive hydrogel developed in his lab, it would assemble itself into a labeled, miniature 3-D model of the bookshelf or crib. Once the model was folded, it’d be immediately clear that it’s in fact Screw 128614 rather than Screw 123756 that goes into Part 100514. So far, Ikea and other furniture stores he’s approached haven’t shown interest.

Related: Packing more punch into polymer devices

Despite the lack of investment from Ikea, self-assembling objects like what Serpe proposed are far from being a parlor trick. Shipping boxes that contain a lot of filler or air is expensive, which is why Ikea packages its products in as flat a form as possible. So researchers like Serpe and NC State’s Dickey and Genzer are committed to finding the right applications for shape-shifting polymers and developing sophisticated systems that can transform from one shape to another when stimulated.

The NC State team in particular has been using different colors of ink to encode folding patterns into printable polymer sheets. The different inks encode the sequence that folding steps would take: A user would shine a specific color of light on a sheet, activating one color of ink—and one set of folds—while leaving the other regions flat. Another color of light would activate other folds, and so on (Sci. Adv. 2017, DOI: 10.1126/sciadv.1602417). The ability to control sequence might one day save on shipping by allowing flat sheets to transform into objects with complex 3-D shapes once removed from their boxes.

Hayward sees this type of stimulated self-assembly as complementing the current trend in 3-D printing. “Two-dimensional printing is still much more rapid and scalable” than 3-D printing, in which parts are built layer by layer, he says. While 3-D printing an object can take on the order of several minutes to hours, printing 2-D shape-shifting polymers would take much less time. For example, roll-to-roll manufacturing of 2-D electronics can churn out about a meter of material per second. Many 3-D printing techniques also require extra struts and supports to be added during the manufacture of objects. These then need to be removed and the printed objects washed of the extra material. Materials that are 2-D printed that self-assemble into 3-D ones would avoid the need for these support materials.

Hayward sees a lot of fertile ground for shape-shifting polymers in electronics because electronics can be difficult to install on 3-D, curved surfaces. Along with Subramanian Sundaram of Massachusetts Institute of Technology and coworkers, Hayward recently printed flat, centimeters-long electronic devices out of layers of polyacrylates and inks that spontaneously stood up on four legs when peeled off the platform they were printed on (ACS Appl. Mater. Interfaces 2017, DOI: 10.1021/acsami.7b10443).

Hold on tight

Star-shaped microgrippers (shown under visible light at top) grab onto cells from a fluorescently labeled clump of connective tissue (bottom) and excise them after their arms close.

Star-shaped microgrippers (shown under visible light at left) grab onto cells from a fluorescently labeled clump of connective tissue (right) and excise them after their arms close.

Credit: ACS Appl. Mater. Interfaces

Shape changes like self-assembly—going from one static form to another—is just the first step toward applications that scientists envision for shape-shifting systems. On-the-fly shape change of an already assembled device is another challenge engineers are taking on.

One area where this is particularly appealing is in medicine. Instead of physically opening up a person to remove a tumor or clear a clogged vessel, doctors would like to send in a device that can complete the task at hand less invasively. But controlling a swallowable or injectable device through centimeters of flesh can be tough.

The hydrogel pNIPAM is particularly appealing because the gel starts to contract significantly at about 32 °C, which means a room-temperature device could begin shape-shifting a few minutes after someone swallows it when it’s exposed to body temperature. Furthermore, pNIPAM, like many gels, is squishy and has no known toxicity.

Related: Pop-Up Liquid Crystals

Research teams such as those of David Gracias and Thao (Vicky) Nguyen at Johns Hopkins University have already shown the potential utility of pNIPAM-based grippers. The points of the star-shaped devices curl inward like a claw when activated. “Let’s say you want to capture a biopsy of a tumor,” Nguyen says. “You could have patients swallow these grippers and guide them to the right tumor so that they can actually grip the tumor and pull some cells off.”

Gracias and Florin Selaru at Johns Hopkins University School of Medicine have deployed soft grippers in live animals, and they can load certain versions with drugs that release over several days. They’re investigating targeting strategies involving grippers that “close” when they encounter enzymes that are overproduced by metastatic tumors (J. Am. Chem. Soc.2010, DOI: 10.1021/ja106218s). Also, one generation of their grippers is doped with iron oxide particles, so the researchers could round up the tiny claws using magnetic fields (ACS Appl. Mater. Interfaces2015, DOI: 10.1021/am508621s). Gracias says his team is currently optimizing the grippers for biocompatibility in advance of regulatory review.

Nguyen has also explored medical applications for polymers in collaboration with MedShape, an orthopedics device company that in 2005 spun out of Ken Gall’s lab at Georgia Institute of Technology. They’ve developed shape-shifting devices that expand in the body to help secure tendons to bone. To function and endure in the high-impact, high-loading environment of the foot or ankle, for example, their materials need to be significantly more robust than current hydrogels and LCEs.

In several of the devices, MedShape uses a proprietary material it calls PEEK Altera. It has a chemical makeup similar to that of regular PEEK (polyether ether ketone), a high-end plastic. But unlike PEEK, before being deployed, objects made of PEEK Altera can be compressed or folded so that doctors can place the smaller forms in patients and mechanically expand them during surgery.

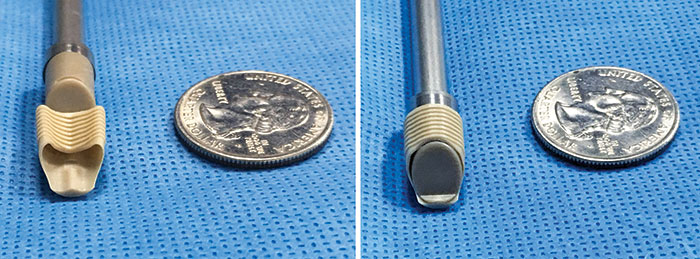

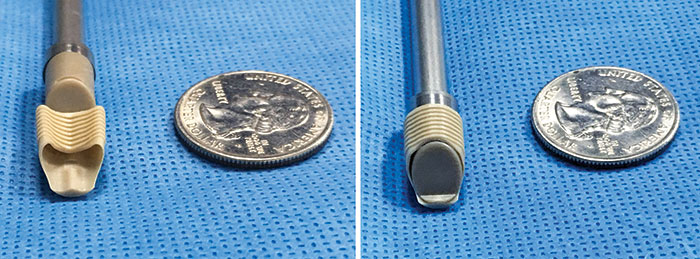

MedShape’s Eclipse PEEK Altera tissue anchor can be compressed (left) and then popped into a rigid, permanent shape once deployed (right).

Credit: MedShape

The company now sells two PEEK Altera devices, including anchors to reattach tendons. A surgeon can tuck a torn tendon inside a small bone tunnel, insert the compressed device, and deploy the device by expanding it mechanically. “A comparable device would be a screw,” says David Safranski, MedShape’s director of basic research. “However, if you’re inserting a screw, you’re rotating it, and that can rotate the tendons and potentially damage them.” MedShape’s anchoring devices simply slide in. And once in, PEEK Altera stays strong and rigid and doesn’t leach into a person’s body, comparable to regular PEEK. Since the company’s first U.S. Food & Drug Administration clearance in 2009, surgeons have put 50,000 of MedShape’s shape-memory devices into people.