Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Improving a plastic-degrading enzyme for better PET recycling

Adding sugars to a cutinase enzyme makes it more effective at breaking down polyethylene terephthalate

by Melissae Fellet, special to C&EN

February 28, 2018

Stabilizing a bacterial enzyme by strategically decorating it with sugars could help it to recycle one of the most widely used plastics and ultimately keep that plastic out of the landfill (Biochemistry 2018, DOI: 10.1021/acs.biochem.7b01189).

Soda, water, and shampoo bottles made from polyethylene terephthalate (PET) are typically recycled by grinding them into small flakes, which are then used to make products such as plastic containers, carpet, industrial strapping, and construction materials. But some of these products cannot be recycled again and eventually end up in landfills or the environment. By using enzymes to break PET into ethylene glycol and terephthalic acid, recyclers could use the recovered ingredients to make new plastic bottles of the same quality. Such a process would allow the material to be repeatedly recycled, helping to solve the growing problem of plastic trash.

Bacteria that cause plant diseases use an enzyme called cutinase to destroy polyester linkages in the tough outer coating of plants. In previous studies, researchers discovered that cutinase can also digest PET and break it down into its monomeric ingredients. Cutinases degrade PET most effectively at around 75 °C, a temperature at which PET chains loosen and have some wiggle room. The extra space around the chains makes it easier for cutinase to attach to the material. But the enzyme doesn’t work long at these temperatures because it begins to unfold and clump with itself.

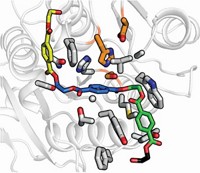

Richard A. Gross of Rensselaer Polytechnic Institute and his colleagues wanted to prevent a bacterial cutinase from forming these inactive clumps. They decided to decorate it in strategic positions with sugars, which keeps the enzyme folded at elevated temperatures and creates physical barriers that make it harder for the enzyme to stick to itself.

Although bacteria do not naturally decorate their proteins with sugars like eukaryotic cells do, the researchers noticed three sites on the cutinase where eukaryotic cells might add a short string of sugars. They then genetically engineered yeast, a eukaryote, to produce a bacterial cutinase originally isolated from microbes found in leaf and branch compost. After producing the cutinase, the cells naturally glycosylated the enzyme at the predicted sites. The researchers purified the glycosylated cutinase and measured its tendency to aggregate by tracking light scattered through a solution of the enzyme at various temperatures.

The glycosylated cutinase began to aggregate and scatter light at temperatures around 80 °C, whereas the nonglycosylated enzyme scattered much more light starting at 70 °C, even forming visible clumps in some tests. The glycosylated cutinase, working at its optimal temperature and concentration, degraded more PET than the nonglycosylated protein.

The improved stability and activity of the glycosylated cutinase is a big step toward optimizing the enzyme to be useful commercially, Gross says.

“This technology could help make one of the most widely used plastics more degradable,” says Lucia Gardossi of the University of Trieste, who uses enzymes to make renewable plastics.

China once processed about half of the world’s plastic and paper trash for recycling. But last year, the country banned imports of 24 types of solid waste, leaving countries looking for solutions to accumulating piles of plastic. “The problem of plastic trash is so urgent, and the development of solutions for managing plastics so fast, that I’m positive enzymes like this will find practical applications in a short time,” Gardossi says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter