Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Safe, water-based lithium battery packs an energy punch

Designer graphite electrode and water-based electrolyte promise low-cost batteries that won’t explode

by Prachi Patel, special to C&EN

May 8, 2019

| A version of this story appeared in

Volume 97, Issue 19

Lithium-ion batteries that use water-based electrolytes instead of flammable solvents would make rechargeable devices safer. But the performance of water-based batteries has been subpar. Now, by designing a novel, high-capacity cathode, researchers have made an aqueous lithium-ion battery that boasts an energy density comparable to commercial devices—and is also less likely to explode (Nature, 2019. DOI: 10.1038/s41586-019-1175-6).

The battery should be cost-effective and environmentally friendly in addition to being safer. That’s because the cathode, made of graphite and lithium halide salts, gets rid of rare, expensive metals such as cobalt and nickel found in conventional cathodes.

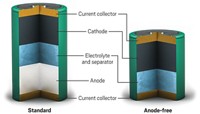

Researchers have been working on water-based lithium batteries for over two decades. One drawback of aqueous electrolytes is that they only work at low voltages, about 1.2 V, so they can’t supply enough power for consumer electronics such as cell phones, which need 4 V. Like any other battery, the challenge has been finding the right combination of electrode and electrolyte material to get high voltage, energy density, and cycle life. For a voltage boost, University of Maryland chemical and biomolecular engineer Chunsheng Wang and his colleagues at the US Army Research Laboratory previously developed water-in-salt electrolytes, which are super-concentrated, sticky gels of lithium salts. By combining these electrolytes with protective coatings for anodes, they made 4V batteries (Science 2015, DOI: 10.1126/science.aab1595).

The team has now focused its attention on the cathode. In a lithium-ion battery, lithium ions move back and forth between the two electrodes. The battery’s energy density depends on how well the electrodes take up and release ions. Most lithium-ion batteries, including aqueous ones made so far, use lithium–metal oxide cathodes and graphite anodes.

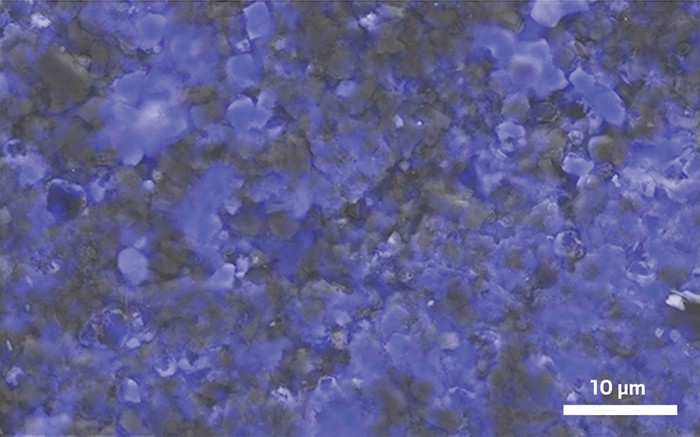

Graphite holds much more charge than the lithium metal oxides because lithium ions intercalate, or slip easily, between graphite’s lightweight carbon layers. So Wang’s group decided to use graphite for the cathode as well. Others have tried this before, using pure graphite for the electrodes and a lithium salt solution as the electrolyte. But these designs consume lithium and other ions from the electrolyte to operate, so they require a large amount of electrolyte, says postdoctoral researcher Ji Chen. This increased mass means the batteries have lower energy density.

To combat that, he and his colleagues preloaded their graphite cathode with lithium bromide and lithium chloride powders. These halide salts do not dissolve in the highly concentrated gel electrolyte—they stay put. But the lithium ions can move, traveling into and out of the cathode when the battery is discharged and recharged. “This process does not involve salt consumption in the electrolyte, so there’s no need for electrolyte in large quantity,” Chen says.

This strategy boosts the cathode’s energy density to 970 Wh/kg, almost twice that of the lithium cobalt oxide cathodes used in smartphone batteries and higher than state-of-the-art nickel- and cobalt-based cathodes. The researchers combined the cathode with a pure graphite anode to make a full lithium-ion battery cell, which has an energy density of 460 Wh/kg, matching that of some of the best commercial batteries.

“This work reports on multiple key milestones for aqueous ion batteries and provides a major leap towards their commercially viable use in stationary storage and possibly even electric transportation applications,” says Gleb Yushin, a materials scientist and engineer at the Georgia Institute of Technology.

However, he says, it’s far from commercial readiness. The researchers will still need to solve multiple scientific and engineering issues in order to compete with state-of-the-art commercial cells, Yushin says. The battery’s capacity, for instance, starts fading after 150 cycles, and it also needs to be stable at a broad temperature range.

Postdoctoral researcher Chongyin Yang says they are now trying to address those issues and are also experimenting with using fluorine at the cathode. “It is one of the lightest elements, and if we could use that, it would further boost energy density,” he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter