Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Inorganic Chemicals

Making aluminum without making CO2

Apple backs new process that promises oxygen as by-product instead

by Michael McCoy

May 16, 2018

| A version of this story appeared in

Volume 96, Issue 21

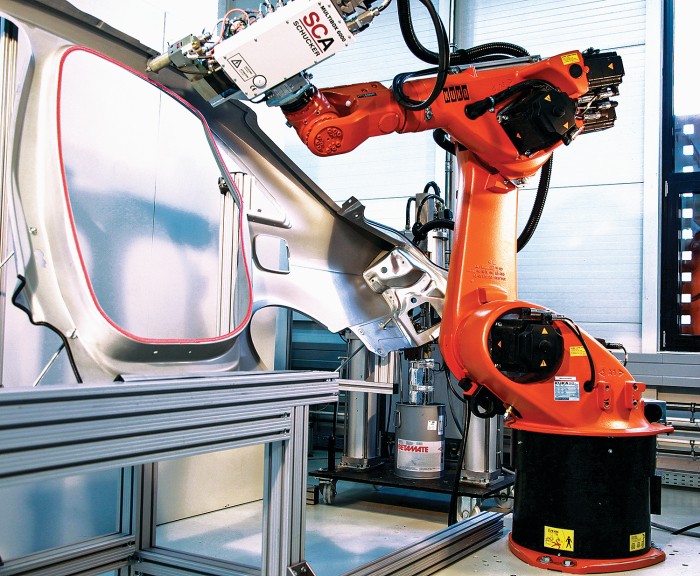

Three industrial giants are getting together to commercialize a new process for making aluminum that generates oxygen as a by-product instead of carbon dioxide.

The companies—aluminum makers Alcoa and Rio Tinto and computer icon Apple—plus the governments of Quebec and Canada will invest a combined $145 million to develop the approach and license it to the aluminum industry.

Aluminum has been made the same way since 1886, when the American chemist Charles Martin Hall and the Frenchman Paul Héroult almost simultaneously developed an electrolytic technique for reducing aluminum oxide in a bath of molten cryolite (hexafluoroaluminate). The process uses a carbon-rich anode that reacts with the generated oxygen to form CO2.

Researchers have sought inert anodes almost since the Hall-Héroult process debuted, according to Donald R. Sadoway, a professor of materials chemistry at MIT. But to date nothing has satisfied tough anode requirements such as physical stability, electrical conductivity, and resistance to attack by fluorine and oxygen.

Alcoa has been testing an inert anode of undisclosed composition since 2009 at a technical center in Pittsburgh. Sadoway notes that Alcoa has published frequently about nickel ferrite cermet anodes, though it likely has moved beyond the metals and alloys previously disclosed.

Apple says the partnership to commercialize the technology emerged after three of its engineers went looking for a better way to produce aluminum, used extensively in its phones and computers. Seeing the potential environmental impact of the Alcoa process, the engineers brought Rio Tinto to the table, Apple says.

Converting Canada’s aluminum industry, the world’s third largest, to the new technology could eliminate greenhouse gas emissions equivalent to nearly 1.8 million light-duty vehicles, the partners say. Aluminum production’s biggest source of emissions is the electricity needed for electrolysis.

Producing oxygen on an inert anode does require more energy that producing CO2 on a consumable carbon anode. Sadoway notes, however, that other benefits of a long-lasting anode should offset the energy gain. Plus, the process won’t generate CF4 and C2F6—both potent greenhouse gases—as by-products.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter