Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Education

Newscripts

Chemist bears Olympic flame, Ionic liquids go bananas

February 6, 2006

| A version of this story appeared in

Volume 84, Issue 6

Chemist bears Olympic flame

MIT chemist Daniel G. Nocera is one of the 10,001 torchbearers carrying the Olympic flame toward Turin, Italy, for the Torino Winter Games being held this month. He ran a 1-km stretch on Dec. 8, 2005, the first day of the relay, as one of the participants for Italgas, the Italian energy company and a sponsor of the 2006 Olympics.

Italgas selected Nocera for the relay after he received the 2004 Italgas Prize for Energy & Environment. Nocera's research focuses on chemical and biological methods for producing energy, including developing photocatalysts to split water into hydrogen and oxygen and to make solar-energy conversion more efficient.

For Nocera, a runner, carrying the torch was a thrill. "I had the opportunity to run a choice leg through the center of Rome," Nocera says. "What I liked best were all the children running along with me on the sidewalks."

The Olympic flame, ignited on Nov. 27, 2005, in Olympia, Greece, is carried in a gas-powered torch. The torch relay is covering 11,300 km as runners crisscross the length and breadth of Italy over 64 days. It will arrive in Turin on Feb. 10 for the opening ceremony.

Nocera was surprised by how big the flame was. "It could have cooked a few low-flying birds," he mused. Nocera will be back in Italy to catch part of the Olympic competition, which runs Feb. 10-26.

Ionic liquids go bananas

Room-temperature ionic liquids are nonvolatile, low-melting-point salts that typically consist of nitrogen-containing organic cations and inorganic anions. They have been much publicized during the past 15 years for their potential as environmentally friendlier alternatives to organic solvents and as "advanced functional materials" such as catalysts and engineering fluids.

Journal editors are justifiably leery of some of the application claims in research papers on ionic liquids, believing that the claims are not industrially relevant and are surrounded by hype. And some confidential sources tell stories of chemists who take to fits of cringing and other odd behavior when they encounter yet another paper on ionic liquids.

Be that as it may, Newscripts was still intrigued by a new paper on ionic liquids that describes the use of 1-butyl-3-methylimidazolium chloride as a solvent to study different stages of fruit ripening, a key analytical test in the food-processing industry (Chem. Commun., published online Jan. 19, dx.doi.org/10.1039/b515177p).

One of the paper's lead authors, chemistry professor Robin D. Rogers of the University of Alabama, Tuscaloosa, has previously shown that the same ionic liquid is useful to dissolve and process cellulose from wood and cotton to make textiles, sensors, and plastics. Rogers and his colleagues, including emeritus chemistry professor Patrick Moyna of the University of the Republic, in Uruguay, and his chemist son Guillermo Moyna, now of the University of the Sciences in Philadelphia, apparently were monkeying around and figured out that the ionic liquid can also dissolve bananas and other fruit.

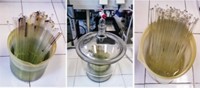

For bananas, the carbohydrate in the edible pulp starts out mainly as amylopectin, which is gradually broken down by enzymes into sucrose, glucose, and fructose--that's the ripening process. The ionic liquids method simply requires dissolving freeze-dried banana samples in the ionic liquid, then obtaining the 13C NMR spectrum of a sample to analyze the sugar content.

The approach significantly reduces the number of steps and the amount of chemicals needed for fruit analysis, particularly volatile organic solvents. According to the junior Moyna, one method requires taking dried banana pulp, then digesting, filtering, gelatinizing, hydrolyzing, and titrating with Fehling's reagent. That kind of analysis is repeated for batches of bananas for up to eight different ripening stages.

The simplicity of the ionic liquids approach should make it amenable to automated analysis of many different types of fruits and grains, Rogers adds. If nothing else, this research paper will make you think twice when you examine the green, green-yellow, yellow, or yellow-brown peel of your next banana.

This week's column was written by Steve Ritter. Please send comments and suggestions to newscripts@acs.org.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter