Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Water Makes Diamond Coatings Slippery

July 7, 2008

| A version of this story appeared in

Volume 86, Issue 27

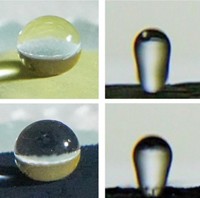

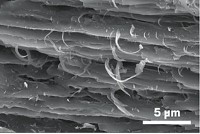

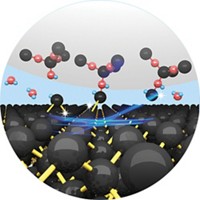

Crystalline diamond is prized as a durable, low-friction coating for the contacting surfaces of high-performance tools and certain machine parts. The reason for diamond's slippery surface, however, has been the subject of much debate. One hypothesis has been that when two surfaces rub together, the carbon surface structure of diamond morphs into a graphite structure. A group of researchers led by Robert W. Carpick of the University of Pennsylvania now provide spectroscopic evidence that the diamond structure is maintained (Phys. Rev. Lett. 2008, 100, 235502). After rubbing together two objects coated with ultrananocrystalline diamond films, which contain diamond grains smaller than 5 nm in diameter, the researchers used X-ray techniques to analyze the worn regions of the surfaces. They found no sign of graphite, but they did find signs of carbon oxidation. They also observed lower friction and less wear in humid conditions. The team proposes that as the surface carbon atoms are stripped off by mechanical friction, water dissociatively adsorbs on the worn surfaces to produce C–H and C–OH bonds that provide lubrication.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter