Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Analytics For Fuel Cells

New tools to probe degradation will help design of longer lasting devices

by Mitch Jacoby

March 30, 2009

| A version of this story appeared in

Volume 87, Issue 13

FUEL CELLS powered by hydrogen and alcohols derived from renewable sources are one promising route to achieving President Barack Obama's vision of energy independence underpinning economic security. In their current state of development, these power devices can generate electricity efficiently and cleanly through electrochemical processes that produce little or no carbon by-products and greenhouse gases. But to advance fuel cells to wide-scale commercialization, various scientific and technical challenges must be overcome, including their currently short useful life.

COVER STORY

Analytics For Fuel Cells

To design longer lasting fuel cells, researchers need to probe, understand, and ultimately control the underlying causes of fuel-cell deterioration. "This area is rich with opportunities for analysis," according to Trung Van Nguyen, a professor of chemical and petroleum engineering at the University of Kansas, Lawrence. He and other speakers at a Pittcon symposium earlier this month hope to attract analytical specialists to study these problems.

"The major issues with today's fuel cells, especially PEM fuel cells, are durability and cost," said Van Nguyen about polymer-electrolyte-membrane (PEM) fuel cells, which are also known as proton-exchange-membrane fuel cells. For these reasons, fuel cells, particularly PEM fuel cells, which are the type generally used to power automobiles, are lagging behind other alternative energy platforms, such as solar-cell and wind-energy technologies.

The cost of PEM fuel cells is "sky high," emphasized Van Nguyen, who currently serves as the director of the National Science Foundation's Energy for Sustainability research funding program. And PEM fuel cells currently don't last long enough to be widely commercialized. According to Department of Energy guidelines, fuel-cell systems for transportation applications should provide power for 5,000 hours and 150,000 miles to be comparable with today's automobile engines. Many PEM fuel-cell systems operate efficiently for just a fraction of that lifetime before the power output begins to decline.

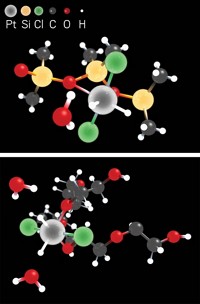

LIKE BATTERIES, fuel cells extract electrical energy from electrochemical reactions that occur at the devices' electrodes. In PEM fuel cells, hydrogen is delivered to an anode where an electrocatalytic material—usually containing a precious-metal catalyst such as platinum—facilitates decomposition of hydrogen into protons and electrons. Protons migrate through an electrolyte medium to a cathode, while electrons travel through an external circuit providing electrical power to a vehicle or other device hooked up to the fuel cell. The protons and electrons react with oxygen at the cathode catalyst layer to produce water, which flows out of the cell.

"The major issues with today's fuel cells, especially PEM fuel cells, are durability and cost."

In PEM fuel cells, a micrometer-thin polymer electrolyte film made of an ion-conducting material, often a perfluorosulfonated polymer such as DuPont's Nafion (perfluorosulfonic acid), separates the anode and cathode. One of the key jobs of the membrane is to conduct protons between the electrodes. That task requires that the membrane remain humidified so that hydrogen ions can dissociate from SO3– groups on the polymer side chains and migrate through the electrolyte film. The membrane must block electrons from diffusing between the electrodes and short-circuiting the fuel cell. It must also prevent fuel and oxygen from leaking through the cell.

To make fuels last longer, researchers need detailed understanding of the processes that degrade the catalyst layer, the catalyst-support material (usually carbon), the membrane, and other fuel-cell components, Van Nguyen said. The fuel-cell industry needs methods to probe the porosity, tortuosity (twists and turns), pore-size distribution, hydrophobicity, and other properties of the catalyst layer, which typically is just 5–10 µm thick, he explained. "It's really difficult to make those measurements on such thin layers," he said, yet those tests are critically important to advancing fuel-cell technology.

The field also needs analytical and imaging tools to measure physical and chemical properties of the interfaces between various fuel-cell components. For example, Van Nguyen stressed the need for techniques to elucidate basic chemical reactions and transport processes at the catalyst-membrane interface and help answer basic questions: What happens when an impurity molecule reaches the interface between a platinum particle and the PEM? How does that event affect the hydrogen-decomposition and water-formation reactions, and what impact does it have on the transport of ions and water across the membrane?

Interfaces in fuel cells change throughout the life of the device due to repeated hydration and dehydration, temperature shifts, and other factors, Van Nguyen explained. Yet after the critical components of a fuel cell are assembled, those interfaces—and their properties, which dictate fuel-cell performance—are hidden and inaccessible to most analytical tools.

RATHER THAN disassembling a used fuel cell to probe how the components changed over time, and risk altering the analytical clues, John W. Van Zee, a chemical engineering professor at the University of South Carolina, Columbia, would prefer to study those effects in situ—that is, in a working fuel cell. That analysis is not done at present because the tools aren't available.

Instead, a researcher who, for example, wants to evaluate the performance of a fuel-cell catalyst, would prepare a catalyst sample (not a complete fuel cell) and measure its electrochemical activity ex situ before and after subjecting the test system to standard voltage-cycling procedures. The shortcoming of that method, according to Van Zee, is that even though the test is designed to isolate the catalytic layer, it does not reveal why electrochemical activity falls over time. It could be due to decreased catalyst surface area resulting from loss of metal particles or agglomeration of metal particles in the catalyst layer, he remarked. Oxidation of the carbon catalyst support (to CO2) also could cause loss of electrochemical activity. New methods are needed to sort through the possible degradation mechanisms.

Platinum alloy catalysts present related analytical challenges. Van Zee cited studies suggesting that alloying platinum with metals such as nickel, cobalt, and iron can boost platinum's catalytic activity. A boost in activity means the fuel cell needs less of the expensive platinum. But the booster transition metals can corrode slowly in the fuel cell and separate from the catalyst layer over time. Determining the extent and rate of that degradation requires a sensitive technique. The challenge, Van Zee said, is to develop a way to measure trace amounts of these metals in a working fuel cell during the course of a few thousand hours of operation.

THE MEMBRANES at the heart of PEM fuel cells present other types of analytical challenges. According to Cortney K. Mittelsteadt, a PEM specialist at Giner Electrochemical Systems, Newton, Mass., water uptake is the most important PEM property because it affects all other membrane properties. For instance, for the membrane to be an efficient ion conductor, it must hold enough water to dissociate and solvate the protons and transport them through the membrane. Similarly, the PEM's water content affects its durability, gas permeability, and mechanical properties.

"This area is rich with opportunities for analysis."

Although water uptake, which depends sensitively on temperature and relative humidity, is vitally important to fuel-cell performance, that property is not easily measured with commercial instruments. To evaluate water uptake in Nafion and various types of perfluorinated and hydrocarbon-based membranes, many of which were studied on behalf of General Motors, Mittelsteadt built his own apparatus. The instrument features a magnetic balance that measures water uptake in a membrane that is isolated in a temperature- and humidity-controlled chamber.

Mittelsteadt took the same do-it-yourself approach to making other types of PEM measurements. For example, he uses a homemade test rig to measure conductivity as a function of temperature and relative humidity. Other testing systems that were designed, built, or modified at Giner are used to analyze PEM gas permeability (undesirable leakage), various mechanical and structural properties, and modes of membrane failure.

"We've made progress in developing fairly quick methods for measuring critical membrane parameters, but there is still plenty of room for help from the analytical community," Mittelsteadt said. In fact, that was his main interest in attending Pittcon—to attract the attention of analytical chemists who might have suggestions for ways to improve these measurements.

Van Zee was thinking along the same lines. He's hopeful that by exposing more people to the important analytical challenges in fuel-cell research today, "we'll be able to reach people who can help us develop new detection methods and accelerate our understanding of the mechanisms that lead to loss of performance."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter