Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Making Graphene In A Flash

Exposing precursor to a burst of camera light induces fast photoreduction

by Mitch Jacoby

July 27, 2009

| A version of this story appeared in

Volume 87, Issue 30

No time to make graphene via conventional routes? Then make it "in a flash."

Northwestern University scientists have just demonstrated that graphite oxide can be converted instantly to graphene via photothermal deoxygenation by exposing the material to a pulse of light from an ordinary camera flash (J. Am. Chem. Soc., DOI: 10.1021/ja902348k).

Because of its low cost and wide availability, graphite oxide is a promising precursor for making graphene-based materials, which are being studied for use in polymer composites and electronics. The oxide is typically treated at high temperature or with potent reducing agents such as hydrazine to yield graphene.

Now, Laura J. Cote, Rodolfo Cruz-Silva, and Jiaxing Huang of Northwestern have shown in a video that the flash method is an instantaneous, chemical-free way to transform graphite oxide, an electrical insulator, into graphene, a conductor, at room temperature.

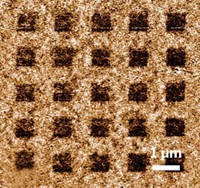

The team has also shown that by applying masking and photolithography methods, the flash technique can be used to fabricate complex patterns, a key step in developing electronic components.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter