Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Examining Explosives

High Explosives Applications Facility researchers tackle science for national security

by Jyllian Kemsley

July 18, 2011

| A version of this story appeared in

Volume 89, Issue 29

From outside, the High Explosives Applications Facility at Lawrence Livermore National Laboratory (LLNL) looks like just another office or laboratory building. Inside, however, some of the nation’s most dangerous chemistry is performed.

HEAF, as the facility is known, is the National Nuclear Security Administration’s designated Center of Excellence for High Explosives Research & Development. Scientists use the facility to synthesize, formulate, and characterize explosive materials. Those tasks play a critical role in nuclear stockpile stewardship by providing a means to understand how components of nuclear weapons age and perform over time. Researchers at HEAF also develop safer explosives to replace older compounds, both for the nuclear stockpile and conventional weapons. And the facility’s energetic materials expertise is further brought to bear in counterterrorism activities, such as explosives detection and mitigation and modeling the effects of improvised explosive devices.

HEAF and the scientists who use it are part of LLNL’s Energetic Materials Center (EMC), which is directed by Jon L. Maienschein. The beauty of the center, Maienschein says, is that it brings all parts of explosives research under one roof, including work by experimental chemists, physicists, materials scientists, and engineers, along with explosives technicians, machinists, electricians, instrumentation specialists, and modelers. Historically, functions were more isolated. “Particularly, you’d put the people making materials far apart because they’re making dangerous stuff, and you’d put the people blowing stuff up far away because they’re dangerous just to think about,” he says. “Here, we’re all in this one building.”

The integrated approach improves cooperation and communication—for example, someone planning an experiment to test a particular explosive formulation works closely with a modeler to ensure the setup includes the diagnostics and monitoring necessary to feed back into further computational work. And simultaneous work on nuclear, conventional, and improvised weapons means that staff are more likely to see connections between different projects that better inform their work overall, Maienschein says.

Generally, an energetic material is a combination of an oxidizer and a fuel. Sometimes the oxidizer and fuel are different compounds, as in common rocket propellants, which incorporate ammonium perchlorate as the oxidizer and a separate polymer binder that both solidifies the formulation and serves as the fuel. In other cases, the oxidizer and fuel are synthesized together into one molecule. In the classic trinitrotoluene (TNT), for example, the oxygens of the nitro groups are the oxidizers and the carbons serve as the fuel.

“Low” explosives deflagrate, which means that they propagate energy relatively slowly by burning, with one part of a material heating the next. Common examples include gunpowder and fireworks. “High” explosives are those compounds that detonate through a shock front that propagates at 5 to 10 km per second. High explosives include peroxides, azides, TNT, and other compounds.

The explosive properties of compounds can be tuned through their molecular structure, crystal structure, and crystal size; by formulating them into mixtures with various binders or other additives; or even by providing physical constraints. For example, the high explosive octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (commonly known as HMX, for a variety of phrases including “Her Majesty’s eXplosive”) has two crystal forms, a “chair” β form and a “boat” δ form. HMX crystallizes in the β form at room temperature and transitions from β to δ at around 165 °C. In an explosion, “the δ phase is often more violent than the β phase,” EMC chemist Elizabeth A. Glascoe says. The volume of HMX also expands with the transition, so depending on how explosives makers want the material to behave, they can either physically constrain the material to keep it in β or give it room to expand into δ.

When working hands-on with explosives, safety is a paramount concern, and safety features are obvious in the warren of hallways of the HEAF laboratories. To start, hallway floors are painted with a white path in the middle. If an explosive detonates next to a concrete wall, it will send a shock wave through the concrete and blow off the far side, Maienschein explains. People carrying samples through the hall must stay on the white path, so that if something happens, it won’t affect an adjacent lab.

Lab entrances are also color-coded: blue for no explosives, green for up to 100 g, orange for 1 kg, and yellow for 10 kg. Labs designed for larger amounts have thicker walls and mazelike entrance halls meant to allow a pressure wave from an explosion to dissipate before it gets out of the room. Whiteboards state how many people can enter a lab and are used to keep track of who’s there. The corridor rated for 10 kg has a system of warning lights to ensure that multiple people don’t enter at the same time and exceed the limit.

Overall, the building is engineered such that an accidental explosion in one laboratory doesn’t affect anything or anyone elsewhere—and no one outside the building knows that anything happened.

To experiment with amounts of explosives from 10 to 90 kg, scientists go to LLNL’s Site 300, located 15 miles to the southeast; for more than 90 kg, they turn to the Big Explosives Experimental Facility in Nevada.

HEAF staff members are also vigilant about what they do and how they do it. HEAF includes synthesis and formulation labs as well as machine shops and testing facilities to explore the properties of explosive compounds and formulations. Work such as mixing explosive crystals with a binder, pressing that mixture into a pellet, and machining the pellet into a specific geometry—slow cutting and turning rates are key, Maienschein says—is done by operating equipment remotely, from behind a blast shield.

HEAF also pioneered the use of femtosecond laser machining for small parts and particularly sensitive explosives. “The pulses are so short that bonds don’t pick up resonance and there’s no heating,” so the material just ablates harmlessly into gas, engineer Jerry Benterou says.

In the two decades since HEAF was built, no one working at the facility has suffered a significant injury, Maienschein says. “One guy wrenched his knee going down the stairs, and one person got her fingers pinched in the tailgate of a truck at the loading dock. We work hard on safety, and we’ve done a good job,” but staff must stay vigilant, he adds.

A major challenge now for researchers at HEAF is work on improvised explosives that might be used by terrorists. Terrorists “want something easy to make and hard to detect,” Maienschein says. “They don’t care about safety, and they don’t care about stability. We have to work hard on our safety to make sure that for our purposes we handle the materials appropriately.”

To understand all explosives’ thermal and mechanical properties and how they age, scientists perform a battery of tests. Some tests are mechanical, such as the “drop hammer” test to measure impact sensitivity or a friction sensitivity assay that involves placing a sample on a ceramic plate and rubbing it with a peg. Other ways to characterize materials include combustion calorimetry, checks of spark or heat sensitivity, and burn rate measurements, which correlate to the violence of an explosion and provide important information for simulations. Such tests inform both basic material handling and weapons safety, HEAF firing operations manager Brian Cracchiola says. The heat sensitivity of torpedo components, for example, determines whether ship personnel, when faced with a fire in the missle bay, should attempt to fight the flames, flood the bay, or jettison the torpedoes.

HEAF also has X-ray and other imaging systems to track crystal sizes and defects, voids between crystals and binder material, and cracks in pressed pellets, all of which can change with age and affect how an explosive will behave. HEAF’s X-ray capability further plays a role in homeland security—the lab prepares and scans “homemade” explosives to look for signatures that can be used by baggage scanners to detect devices, engineer Dan Schneberk says. Scientists have developed materials that mimic those signatures for the Transportation Security Administration to use for training personnel.

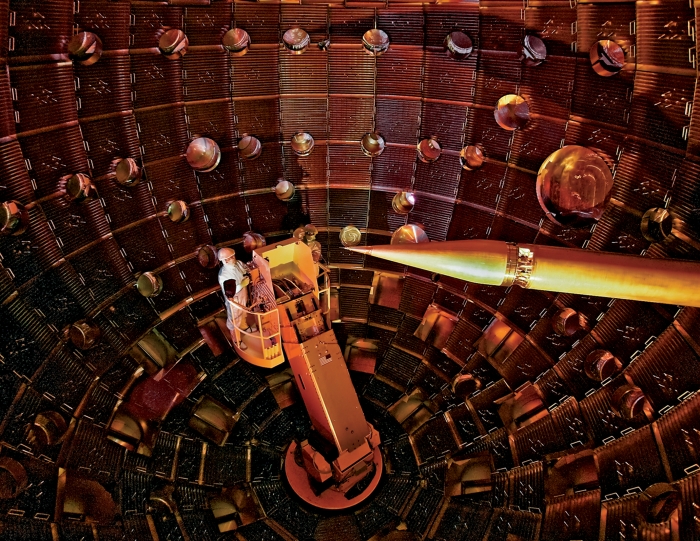

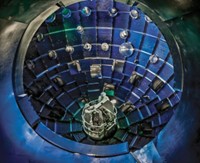

HEAF has several firing chambers for explosion tests, including two for up to 1 kg of material and one for up to 10 kg. Experiments in the tanks are typically heavily monitored and analyzed. Wires and sensors embedded in an explosive material track temperature, pressure, strain, and explosion propagation. If a material is encased in something like a copper tube, how that tube deforms or blows apart also yields information on an explosive’s properties. Sensors track the velocity of flying pieces, and high-speed cameras can record the whole performance.

A new flash X-ray system, called Hydra, allows scientists to peer into a material as it detonates in a firing chamber, to see things such as what happens to a detonation shock front when it hits a void in the material. People had assumed—and modeled—that large voids in explosive formulations affect the detonation front. “It turns out that once the detonation is established, it doesn’t care about the voids,” says John D. Molitoris, a physicist and the EMC group leader for dynamic experiments. Deflagrations, however, are greatly affected by voids, which can change the symmetry of how a material burns and the degree of violence.

A separate gun tank also enables researchers to do “insult” tests to see what would happen when a bullet or some other projectile hits an explosive or other material. “If you want to know what happens to the fuselage of a B-52 bomber if an AK-47 shoots at it, we can do that,” firing operations manager Cracchiola says. Also, if someone has an idea for how to disable roadside bombs by shooting at them, HEAF can test the approach.

In addition to characterizing existing explosives, work at HEAF includes synthesis of new explosives that are safer than compounds currently used in weapons. Although no explosive compounds are thermodynamically stable, some are more so than others—but with that stability can come a trade-off in power.

Triaminotrinitrobenzene (TATB), for example, is very insensitive to impact and friction—it has a crystal structure in which the rings line up in parallel, so layers slide across each other to easily dissipate friction energy. HMX, on the other hand, is harder to handle than TATB—HMX is more heat sensitive and has a herringbone-like crystal structure, so friction can tear up the molecules and set off an explosion. But HMX is also a more powerful explosive than TATB.

“It’s a fine line to walk between having something be stable and ‘handleable,’ and also have the necessary explosive energy,” Maienschein says. LLNL is aiming to split the difference between TATB and HMX with 2,6-diamino-3,5-dinitropyrazine-1-oxide (called LLM-105, for Lawrence Livermore Molecule-105). Compared with other high explosives, LLM-105 has middle-of-the-road energy output and sensitivity, making it relatively easy to handle and unlikely to detonate accidentally, but still has enough power to kick off a plutonium charge in a nuclear weapon.

First made nearly 15 years ago, LLM-105 is slowly making its way up the development chain. LLNL has made nearly 200 molecules to date, and LLM-105 is one of a handful that may see actual use in weapons, physicist Thomas Lorenz says. For the nuclear complex, which has stringent requirements for safety, long-term stability, toxicity, and high energy density, “you get one explosive every generation,” Lorenz says.

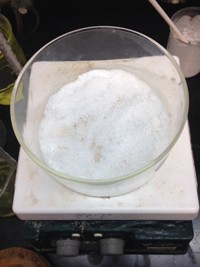

One difficulty with LLM-105 has been synthesis scale-up, says Philip F. Pagoria, EMC group leader for explosive synthesis. Along with standard considerations for taking a synthesis to manufacturing scales, such as cost of materials and waste-stream disposal, there’s the fact that synthetic intermediates themselves may be explosive. The original LLM-105 synthesis had two issues, Pagoria says: a costly and difficult-to-source starting material plus two explosive intermediates. Pagoria’s group has now streamlined the preparation to make 2,6-diaminopyrazine-1- oxide, which is then nitrated to yield LLM-105.

Other projects at HEAF dive into the fundamental chemistry and physics behind what happens in a detonation, with an eye toward what makes a particular compound more or less safe to handle. “When we try to make new molecules, we can’t predict whether one will be a safe one and one will be a bad one,” chemist Laurence E. Fried says. “We’d like to be able to do that.”

Advertisement

Studies of TATB, for example, show that the detonation process makes nitrogen-containing heterocycles, slowing down final decomposition, whereas nitromethane detonation makes smaller molecules. One indication of safety may be whether detonation products are complicated and can slow down reaction kinetics, Fried says. EMC researchers have also found that some materials under detonation conditions act more like molten salts than solids, with hydrogen atoms moving and reacting faster than heavier carbon or oxygen.

The integrated approach that EMC and HEAF take for unraveling these problems is key to their success, Maienschein says, and goes back to lab founder Ernest O. Lawrence. “The Lawrence hallmark was integrated teams,” Maienschein says. With the triple mission of stockpile stewardship, better and safer weapons, and counterterrorism, there’s probably no more powerful approach.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter