Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Integrating Man And Machine

Materials science developments advance the integration of electronics and tissue

by Celia Henry Arnaud

December 24, 2012

| A version of this story appeared in

Volume 90, Issue 52

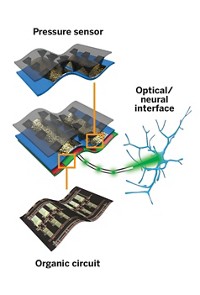

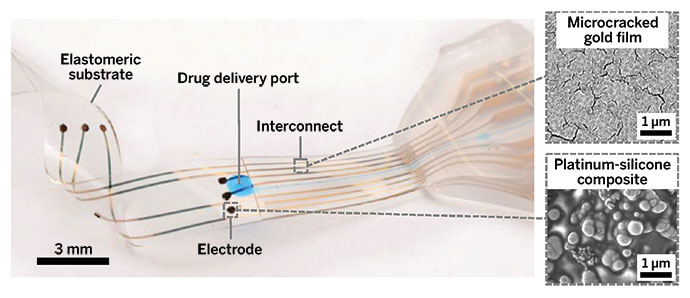

Fictional cyborgs and characters such as Data—the humanlike android on “Star Trek: The Next Generation”—may have gotten a little closer to reality this year. C&EN reported on several advances in integrating electronics with tissue. Until now, these efforts had been restricted to the tissue surface. But a team headed by Charles M. Lieber of Harvard University and Daniel S. Kohane of Harvard Medical School integrated electronics in tissue in three dimensions (C&EN, Sept. 3, page 13; Nat. Mater., DOI: 10.1038/nmat3404). They cultured cells on a scaffold of a silicon nanowire mesh studded with field-effect transistors. They were able to detect electrical signals from cardiac cells grown on the scaffold. Then there’s John A. Rogers and coworkers at the University of Illinois, Urbana-Champaign, who were more concerned about being able to dispose of implantable electronics. They designed ultrathin silicon integrated circuits on a silk substrate—the circuits simply dissolve at the end of their useful life (C&EN, Oct. 1, page 9; Science, DOI: 10.1126/science.1226325). On another front, Zhenan Bao and coworkers at Stanford University moved a step closer to electronic skin that can heal itself—a hallmark of natural skin. They developed a composite material made of a hydrogen-bonding polymer network embedded with nickel microparticles that can restore both its electrical properties and its mechanical properties after being damaged (C&EN, Nov. 19, page 8; Nat. Nanotechnol., DOI: 10.1038/nnano.2012.192). Bao and her coworkers want to use the composite as electronic skin for robots or biomimetic prosthetic devices. In another development, a team from the University of Michigan led by Daryl R. Kipke, Nicholas A. Kotov, and Joerg Lahann advanced toward a goal of developing electrodes that interface neurons with brain-controlled prosthetic devices (C&EN, Nov. 19, page 39; Nat. Mater., DOI: 10.1038/nmat3468). The electrodes, which are made from 7-μm carbon fibers coated with four polymer layers, are small enough to measure the electrical activity from individual neurons.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter