Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Movers And Shakers

U.S. Army bioengineer develops high-tech fabrics to keep soldiers warm, dry, and safe

Paola D’Angelo discusses how her team develops high-performance textiles to protect and support soldiers on the battlefield

by Prachi Patel, special to C&EN

May 16, 2018

| A version of this story appeared in

Volume 96, Issue 21

Paola D’Angelo’s mission is to help U.S. soldiers accomplish theirs. At the U.S. Army Natick Soldier Research, Development & Engineering Center, the bioengineer develops high-tech fabrics for combat clothing to keep soldiers safe and comfortable and to help them be more effective in the field. As part of a previous project to make a fabric capable of sensing biological and chemical weapons, she developed a polymer-gel-based coating that can sense anthrax spores. She spoke with Prachi Patel about her latest project on a heating textile that keeps soldiers’ extremities warm and absorbs sweat—and what it’s like working as a civilian researcher for the Army.

What brought you to the U.S. Army’s Natick center?

My dad was a colonel in the Colombian army. Many of his friends and my friends’ parents were in the military. When I moved to the U.S., I considered joining the Army. That plan fell apart, but I still wanted to be involved or help in some way.

Vitals

▸ Hometown: Worcester, Mass.

▸ Studies: B.S., chemical engineering, 2005, M.S., biomedical engineering, 2008, and Ph.D., biomolecular engineering, 2012, Worcester Polytechnic Institute

▸ Years of research experience: 13+

▸ Favorite book: “One Hundred Years of Solitude,” by Gabriel García Márquez

▸ Favorite movies: The Harry Potter series

▸ If I weren’t a fabric innovator, I’d be: A food critic

I got my chance in graduate school at Worcester Polytechnic Institute. My thesis adviser’s husband worked at Natick, so I asked her if I could work on a project that would serve the military. That was right after 9/11, at the time of the anthrax attacks. I was working on a Ph.D. in biomolecular engineering, and my master’s research had been on ways to kill bacteria. It was the perfect fit. So I worked in conjunction with Natick to understand how anthrax spores germinate and become deadly and how we can come up with a way to kill them. After my Ph.D., I became a postdoctoral researcher at Natick and then was hired as a civilian.

Why is a soldier’s clothing important?

Their life can depend on it. A soldier’s clothing needs to be catered to the environment that they are working in. For instance, one problem that paratroopers have right now is inadequate gloves. When they jump from 10,000 or 20,000 feet [3,000 or 6,000 m], their hands get so cold that they have problems with dexterity. The time it takes to get feeling back in their fingers is valuable if they need to operate weapons or machinery as soon as they land. Plus, numb fingers are just uncomfortable. Soldiers who work in Arctic conditions face this problem all the time.

What research are you doing to design better gloves for these soldiers?

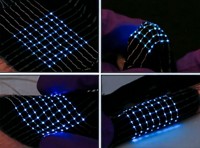

We are developing a heating textile based on a silver nanowire coating to protect soldiers in extreme cold. I have found a way to coat different types of fabric by depositing a solution of nanowires to form a continuous, conductive network. Applying a voltage to one end of the fabric makes the whole fabric heat up within seconds. We plan to apply these textiles to gloves that would heat a soldier’s hands within seconds at temperatures down to −40 °C. The silver layer is less than 100 nm thick, so it doesn’t add any weight.

We are now starting to look into power sources. We don’t want to use heavy batteries, because soldiers already carry so much weight in batteries for radios and other equipment. So we’re partnering with Sheng Xu, a professor at the University of California, San Diego, who has developed a flexible, stretchable battery that is thinner than a hair. We are trying to develop the technology and apply it to our textile.

What other high-tech fabrics are you making?

I am working with Natick chemist Elizabeth Hirst on a hydrogel coating that will be incorporated into textiles to increase comfort in cold conditions. Soldiers in the Arctic have to wear so many layers of clothing that sweat accumulates in places like the shirt cuffs and neck, where it freezes because there’s no way for it to evaporate. The hydrogels would absorb that sweat, and when soldiers get back to camp or base, they can dry the garment and reuse the hydrogel.

We’re also developing textiles that detect and respond to changes in temperature. We use liquid crystals, the same material used in LCD screens. Liquid-crystal molecules change their conformation or orientation based on the temperature. The idea is to integrate them into textile fiber so that the garment protects against temperature changes. Basically, liquid crystal rearrangement would cause the pores of the textile to open to make it more breathable in a hot environment or to close if the soldier is in a cold environment.

Advertisement

None of these coatings would go in the entire garment. They would only go into specific zones that we know are problematic.

How do you test these high-tech fabrics and get them battle ready? When is a new clothing technology ready for a soldier to wear?

Right now, we are working with very small swatches—ranging from one inch to maybe a foot [2.5–30.5 cm]—trying to optimize our technology to make sure it works in different environments and that we can wash and reuse it. Natick has these large shipping-container-sized test chambers that can mimic any environment on Earth. We put our swatches in the chambers and adjust humidity and temperature so they mimic Arctic conditions.

After basic and applied research, we partner with industry to produce yards of this textile. Then we make garments and test them with soldiers, either in the test chambers or in Alaska. Our textile technologists, who find fabrics for specific purposes and design soldiers’ uniforms, go to our bases in Alaska and have soldiers try the garments while conducting their regular exercises. The soldiers give feedback on what they like or have problems with. It’s a continual back-and-forth process to optimize the technology until the new fabrics are ready for use. I’m an engineer, but I work closely with the textile technologists to meet the soldiers’ requirements.

All of this can take quite a few years. But right now, Special Forces are having problems with the gloves they use. They’re really trying to push silver nanowire technology, so instead of taking 10–15 years, it could take five.

As a researcher, what’s it like working with military personnel?

At Natick, recently enlisted soldiers volunteer to help us with research. They signed up to make the country better and to protect it. These are young, new recruits in their late teens and early twenties, and they are very eager to help. As a scientist, it’s nice to see products that were created using technology from your basic lab research, especially since those products are going to help our soldiers.

Prachi Patel is a freelance writer. A version of this story first appeared in ACS Central Science: cenm.ag/dangelo. This interview was edited for length and clarity.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter