Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Batteries need a boost to fly the friendly skies

Lithium-air batteries are a front-runner to power regional electric air travel, but they haven’t yet left the lab bench

by Tien M. Nguyen

October 27, 2019

| A version of this story appeared in

Volume 97, Issue 42

In August, a two-seater plane crashed into a lake in Norway. Afterward, the abandoned aircraft, its passengers unharmed, appeared in photographs with the plane’s tail jutting into the air. The words printed on either wing were upside down yet easy to read: “Avinor” and “100% electric.”

For Avinor, the state-run Norwegian company that owns the plane, the accident was a serious setback. Its downed aircraft was the first electric model in the world approved for commercial production, according to the company. And last year, the firm was tasked by Norway’s government with developing a plan to make all domestic flights electric by 2040.

Norway isn’t alone in its ambitions for green aviation. As the climate crisis worsens, governments and consumers worldwide are looking to reduce air travel’s environmental impact. Flights generate 2.7% of energy-related carbon dioxide emissions worldwide. And they emit NOx and leave behind climate-changing contrail clouds that scientists have linked to an estimated 16,000 premature deaths every year (Nat. Energy 2018, DOI: 10.1038/s41560-018-0294-x).

More than 170 programs aiming to develop electric aircraft are underway globally, with about half of them dedicated to urban air taxis that could transport residents from one end of a city to another, according to an estimate by Roland Berger, a German consulting firm. Whether these planes get off the ground depends, mainly, on their electrical power source: their batteries.

For small, short-distance electric aircraft like the one that crashed in Norway, makers are adapting lithium-ion batteries, a common technology already on the market (and recently recognized with a Nobel Prize). Creating batteries for bigger planes, capable of traveling farther, poses a much bigger problem. Today’s best Li-ion batteries have a specific energy—or energy per unit mass—of around 250 W h/kg, which falls short of the 800 W h/kg scientists say is needed to keep a Boeing 737–sized aircraft in the air for a 1,111 km journey (about the distance from Chicago to New York City).

“Lithium ion is not going to get us there,” says John W. Lawson of NASA’s Ames Research Center. Over the summer, his team of collaborators, which included researchers at Ames; NASA’s Glenn Research Center; NASA’s Armstrong Flight Research Center; the University of California, Berkeley; Carnegie Mellon University; and IBM Research–Almaden, wrapped up a 3-year research project to evaluate another technology that might: the lithium-air battery.

Scientists have calculated that Li-air batteries (technically, Li-O2 batteries) could have a maximum specific energy of 3,460 W h/kg, far greater than what’s needed to power large passenger planes (see page 25). A bonus feature, Lawson says, is that the oxygen for these batteries might be supplied by the plane’s onboard air storage and filtration systems, which send air to the cabin and passengers’ drop-down emergency masks.

Li-air batteries’ potential has tantalized scientists ever since the technology’s introduction decades ago. But a spate of obstacles, such as extreme degradation that eats away at the battery’s insides as it charges and discharges, has tempered the field’s expectations. No commercial Li-air battery yet exists; at the moment, the technology is limited to the lab. In recent years, however, researchers have gained a better understanding of these roadblocks, reinvigorating their attempts to make Li-air batteries one day take flight.

In 1996, K. M. Abraham and Zhiping Jiang at EIC Laboratories filed the first patent for a rechargeable Li-air battery. That one worked with a non-water-based electrolyte. Water-based Li-air batteries, which have lower calculated specific energies than their nonaqueous counterparts, emerged about a decade later with only limited examples. The discovery of the non-water-based batteries, Abraham says, happened by accident.

Abraham had been working on a Li-ion battery when he noticed voltage readings that were slightly off. He realized that the strange measurements were due to air sneaking into the system, so his team started intentionally introducing oxygen into its battery setups, eventually leading to the Li-air battery.

Although its origin was inspired by Li-ion technology, the Li-air battery has a much more complicated chemistry, Abraham says. The components inside Li-ion batteries don’t change much during charging and discharging, for instance. Li-air batteries, on the other hand, have to undergo several phase changes. “Whenever there are phase changes, there will be problems,” Abraham says.

Li-ion batteries are generally made of an organic electrolyte, a graphite anode, and a lithium cobalt oxide cathode connected by a circuit. Discharging them pushes electrons through the circuit and pushes lithium ions through the electrolyte from one electrode to the other. When you charge them, everything runs in reverse. A key feature that makes this design so popular is that the lithium ions trickle into and out of the pores of the anode and cathode without significantly changing their structure and volume.

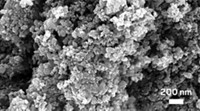

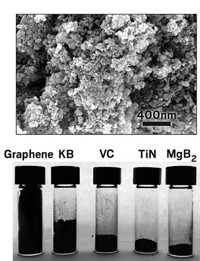

By volume, Li-air batteries are made mostly of an organic electrolyte, a porous carbon cathode, and a lithium-metal anode. The porous carbon cathode material remains empty until oxygen arrives. Discharging a Li-air battery takes place through a two-step chemical process: first, the battery “breathes in” oxygen through the porous cathode to oxidize the lithium-metal anode. Solid lithium superoxide (LiO2) forms at the cathode while electrons travel through the circuit for use. During the second step, the electrolyte dissolves the LiO2, which reacts with itself to form solid lithium peroxide (Li2O2), also in the cathode. Charging the device breaks down the Li2O2. This means that each charging cycle significantly changes the size of the cathode.

Battery researchers are working to solve Li-air batteries’ many challenges, including stabilizing the cathode, protecting the anode, and efficiently delivering oxygen while keeping out other gas contaminants. But perhaps the technology’s biggest problem is that the electrolyte decomposes rapidly because of destructive species formed inside the battery, limiting its rechargeability. To power aircraft, Li-air batteries need to withstand a practical number of charging cycles; for instance, current Li-ion batteries last for thousands of cycles. Scientists don’t yet know if this will be possible for Li-air batteries, NASA’s Lawson says.

But his team is working to find out.

The NASA researchers have built research-quality Li-air battery packs for demonstration in the context of powering electric aircraft, according to Lawson. Each pack is a five-cell unit made of a lithium-metal anode, a porous carbon cathode, and an ether-based electrolyte. With this setup, the team calculates, it should have a practical specific energy of about 200 W h/kg at the cell level. This is only about 5% of Li-air batteries’ elusive theoretical maximum specific energy, Lawson says. But he thinks that when optimized, the battery pack could reach 700–800 W h/kg, the estimated energy requirement for regional planes. The team also ran a simulation of a flight profile, including takeoff, cruising, and landing. Model calculations indicated that the optimized Li-air battery could handle the power requirements for electric aircraft, Lawson says.

But like many other Li-air batteries demonstrated in the lab, NASA’s battery currently lasts for only a handful of recharging cycles. By switching the electrolyte from an ether-based liquid to one made of inorganic molten nitrate salts, the team raised the number of cycles from about 5 to 25. Inorganic electrolytes have previously been shown to be stabler than ether-based ones (J. Am. Chem. Soc. 2016, DOI: 10.1021/jacs.5b11744). They’re also generally safer than organic electrolytes, which can catch fire, as demonstrated by the defective Samsung Galaxy Note 7 phones that were banned from planes by the US Federal Aviation Administration in 2016.

Many researchers, including battery expert Yang Shao-Horn and organic materials chemist Jeremiah A. Johnson of the Massachusetts Institute of Technology, are on the search for better electrolytes.

“None of the known lithium-ion electrolytes are stable for Li-O2 chemistry,” says Shao-Horn, who has worked on Li-ion batteries for more than 20 years. For decades, she says, researchers in the battery field have focused on just a few electrolyte materials. So a few years ago, she decided to knock on Johnson’s door to get a fresh perspective.

“From an organic chemistry perspective, the challenge of Li-O2 is that you’re basically asking an electrolyte to face many of the harshest reactive oxygen species possible,” including singlet oxygen, Johnson says. Scientists have proposed that singlet oxygen arises from lithium superoxide, either when the compound breaks down or when it gets oxidized during charging. “That’s why when people use the same electrolytes used for Li-ion batteries, where those reactive species don’t exist, they often don’t work. They degrade very rapidly upon charging of the cell.”

Together, Shao-Horn’s and Johnson’s labs developed a framework to identify electrolyte molecules that could survive Li-air batteries’ conditions (J. Mat. Chem. A 2017, DOI: 10.1039/C7TA08321A). An ideal electrolyte molecule would meet four criteria: its hydrogens would be bound strongly to the compound to avoid being plucked off by radicals, it would have a high pKa so it can’t react with bases and degrade, it would lack sites vulnerable to nucleophilic attack, and it would be able to resist electrochemical oxidation. This dream electrolyte would possess all these features while also being able to perform its primary job inside the battery, which is to solubilize lithium ions and ferry them back and forth between electrodes.

That’s a tall order for any molecule, but Shao-Horn and Johnson think it exists. This past summer, they published work on sulfamide- and sulfonamide-based electrolytes in a Li-air battery (Chem 2019, DOI: 10.1016/j.chempr.2019.07.003). One robust molecule in particular, N,N-dimethyl-trifluoromethanesulfonamide, resisted degradation for greater than 90 cycles in a Li-O2 battery cell below 4.2 V.

Next, the MIT team hopes to take what it’s learned and incorporate these functional groups into a solid, polymer-based electrolyte, which would also be safer than flammable liquid organic electrolytes.

Another looming challenge for Li-air technology in an airborne setting is whether the batteries can run on air rather than pure oxygen. Laboratory-scale batteries have so far run on purified O2, but ambient air includes nonoxygen constituents, such as carbon dioxide and water.

Water has long been thought of as problematic for nonaqueous Li-air batteries because it can react with lithium metal to form unwanted lithium hydroxide, which is difficult to break down. But recent experiments suggest that this side reaction requires more water than scientists thought, which makes operating the battery in air much easier, says the University of Oxford’s Peter Bruce, who has been working on Li-air batteries over the past decade. To get around any problems that carbon dioxide might cause in Li-air batteries, Bruce suggests that researchers could apply carbon-capture technology, which pulls CO2 from gas streams, to air-processing systems on planes.

Although Li-air batteries haven’t entered the market, manufacturers have shown interest in developing the batteries. IBM ran a robust research program for developing Li-air batteries earlier this decade, but the firm has since shifted away from this type of battery. Samsung recently reported a Li-air battery that has a folded cell structure a few hundred micrometers thick and contains a proprietary polymeric electrolyte that achieved a specific energy of 1,214 W h/kg. In terms of rechargeability, the team demonstrated that a cell with a specific energy of 300 W h/kg could cycle eight times (Joule 2018, DOI: 10.1016/j.joule.2018.11.016).

For now, Li-air technology has a long way to go before becoming practical, for electric aircraft or any other use. But researchers are still eager to see how far Li-air batteries’ development can go. “Recent progress has been very encouraging,” Bruce says, adding that “we haven’t come up against any showstoppers.” So they’re not only eager—they’re optimistic.

Tien Nguyen is a freelance science writer based in Washington, DC.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter