Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Greener batteries for grid storage

An unconventional design doubles the storage capacity of a low-cost, and nontoxic battery for the renewable grid

by Prachi Patel, special to C&EN

March 24, 2020

By standard definition, a battery is a device made of two electrodes and a shared electrolyte solution that chemically connects them. Ditching this conventional design has now enabled researchers to make a type of environmentally friendly battery that overcomes some common technological limitations. By using a different electrolyte at each electrode, researchers have made a novel zinc-manganese battery that could hold large amounts of energy needed for the grid, while keeping costs low (Nat. Energy 2020, DOI: 10.1038/s41560-020-0584-y).

High-energy, durable, and inexpensive energy storage is key to enabling widespread use of intermittent renewable energy sources like wind and solar. But today’s technologies have their trade-offs. Lithium-ion batteries are the most popular grid-scale option given their high energy densities of over 200 Wh/kg. But they are expensive. To be deployed widely, batteries need to cost half of what lithium-ion does. Lead-acid batteries are a less expensive alternative, but they don’t hold much energy per weight and use toxic lead.

Aqueous zinc batteries that use abundant materials and water-based, non-flammable electrolytes are one potential alternative. These batteries are cheaper to make on large scale, and are safer than lithium-ion. But they have had low energy density and typically don’t last long.

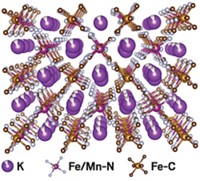

A team of materials scientists and engineers at Tianjin University led by Cheng Zhong and Wenbin Hu decided to improve on the zinc-manganese chemistry used in common disposable alkaline batteries. These batteries have a zinc anode, a manganese dioxide cathode, and a single electrolyte made of alkaline potassium hydroxide. During discharge, the cathode reacts with water and produces hydroxyl ions that react with the zinc at the anode to produce electricity. They are not rechargeable because the reaction at the cathode creates chemical species such as Mn(OH)2 and Mn2O3 that are irreversible. Substituting an acidic electrolyte, which does not support the reactions that form these species, can make the cathode reaction reversible. But too much acid eats away at the zinc.

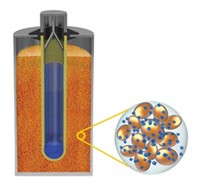

So Zhong, Hu and colleagues figured out how to have their cake and eat it too. They separated the battery cell into three chambers separated by ion-exchange membranes. The zinc anode sits in alkaline potassium hydroxide electrolyte on one side, while manganese dioxide is in an acidic electrolyte of sulfuric acid and manganese sulfate on the other. The middle chamber contains a neutral potassium sulfate electrolyte.

With both electrodes operating in their preferred environment, the reactions at each electrode become reversible, and the voltage of the battery nearly doubles. The new battery has three times the energy density of a lead-acid battery.

“The decoupled zinc-manganese dioxide battery has overwhelming advantages in voltage and energy density over previous zinc-manganese dioxide batteries,” says Junrong Zheng, a chemist at Peking University. However, he says the need for an expensive and potentially short-lasting ion-exchange membrane is a potential hurdle to scaling up this technology.

Hongjin Fan, a physicist at Nanyang Technological University, points to the same potential limitation, though he calls the decoupled electrolyte approach smart and promising. He expects that separating the highly concentrated acidic and alkaline electrolytes will strain the membranes. “Gradually the whole electrolyte will neutralize,” he says, “leading to lowering of the cell voltage and corrosion of zinc.”

Zhong is aware of this problem, and says the team is already working on designs that don’t use membranes. And for now, he adds, “we have signed contracts with some local power stations to jointly study the prospects of these batteries in practical applications.” They are testing a small 20 kWh energy-storage system—enough to provide most of the energy needs of an average US household—that combines solar panels with their batteries—.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter