Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Renewables

A renewable energy take-back program

How First Solar recovers 90% of materials from its CdTe panels

by Melody M. Bomgardner

April 9, 2018

| A version of this story appeared in

Volume 96, Issue 15

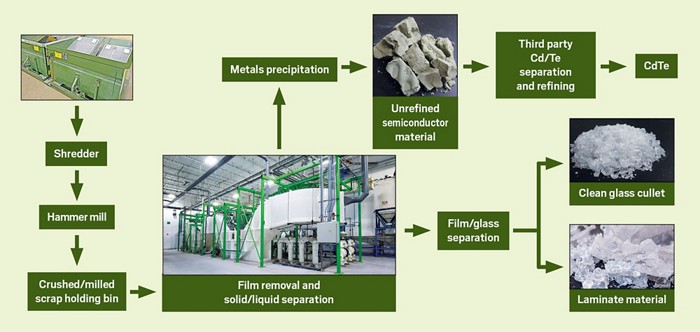

First Solar separates the cadmium telluride semiconductor from old panels’ glass and polymer sheets, then reclaims and purifies the material for use in new panels.

Source: First Solar

Many companies produce photovoltaic modules, but First Solar is the only one in the world that has an end-to-end recycling process.

The company started selling modules in 2002 and now has about 5% of the solar market. Instead of crystalline silicon, First Solar’s photovoltaics are based on a thin-film cadmium telluride semiconductor. The firm’s recycling process, which started up in 2005, runs alongside manufacturing at its facilities in the U.S. and Malaysia. First Solar has a stand-alone recycling facility in Germany and plans to include recycling at a plant it is building in Vietnam.

Customers can choose whether to have the company reclaim their old modules—and most do. “As long as we keep bringing the cost down we will keep getting the material,” says Sukhwant Raju, First Solar’s global recycling director.

First Solar reclaims and reuses 90% of the panels’ semiconductor material, Raju says. “We have been very focused right from day one to have a closed-loop process. As we improve panels we want to improve recycling.”

The company’s process is now in its third generation. First, the panels are crushed and shredded. A chemical process separates the semiconductor material from the glass and the glass is recovered. Then the semiconductor material is cleaned, separated, and refined in a chemical process so that it can be used in new panels. First Solar has streamlined the process so it does not produce effluent.

Raju says First Solar’s end-to-end process is so efficient that the company might move into crystalline silicon panel recycling. Though the materials differ, the process is similar enough, he contends. “It’s just incremental change for us. We already have the equipment, the labor, and the experience. It’s just ‘go and install another line.’ ”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter