Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Persistent Pollutants

Imports of used PFAS into US scrutinized

Regulators examine Chemours’s shipments of GenX fluoroethers to North Carolina for reprocessing

by Cheryl Hogue

March 3, 2019

| A version of this story appeared in

Volume 97, Issue 9

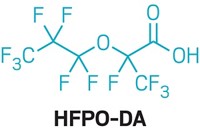

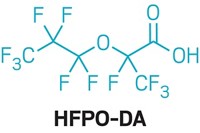

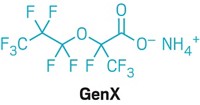

To meet demands for nonstick-pan coatings and fuel-cell components, Chemours depends on a fluorinated chemical called GenX. This compound helps building-block materials link together into tough, resistant plastics and industrial membranes. During the process of making these materials, GenX, an ammonium salt, ends up in water and hydrolyzes into hexafluoropropylene oxide dimer acid (HFPO-DA). The three Chemours plants that use GenX extract HFPO-DA from process wastewater so the material can be remade into GenX.

Now, as environmental concerns about these fluorinated chemicals mount, Dutch and US environmental regulators are taking a close look at Chemours’s practice of shipping reclaimed HFPO-DA from its plant in the city of Dordrecht, the Netherlands, to one in Fayetteville, North Carolina. In addition, Dutch authorities are raising concerns about the environmental release of HFPO-containing material as it is hauled for reprocessing or disposal.

Chemours’s Fayetteville Works facility manufactures virgin GenX. For years, it has also made GenX from HFPO-DA reclaimed from operations at its site as well as at Chemours plants in Dordrecht and outside Parkersburg, West Virginia, company spokesperson Lisa Randall tells C&EN. Making GenX from captured HFPO-DA leads to lower emissions of fluoroethers into the environment than does manufacturing the material from scratch, Chemours says in a Jan. 25 statement. HFPO-DA is toxic, the US Environmental Protection Agency and Dutch authorities say. The substance contaminates surface water, groundwater, or both around all three Chemours fluorochemical factories. Both GenX and HFPO-DA are nonpolymer per- and polyfluoroalkyl substances (PFAS), a class of chemicals that are persistent or break down into persistent compounds.

North Carolina has been especially hard hit with HFPO-DA pollution. State regulators have struggled to address the contamination since HFPO-DA and other fluoroethers turned up in municipal drinking water drawn from the Cape Fear River downstream of Fayetteville Works a few years ago. Plus, high levels of HFPO-DA were discovered in private wells near the facility.

State officials did not know that the Fayetteville plant was receiving HFPO-DA material from the Netherlands until early last year, according to documents the North Carolina Department of Environmental Quality supplied to C&EN. State regulators wrote to the facility in January 2018 seeking details about the imports, including the average volumes sent to the plant per month. Most of Chemours’s response consists of confidential business information and can’t be released to the public, an agency spokesperson says.

Fayetteville Works hasn’t been the only destination for the Dordrecht plant’s captured HFPO-DA. For years, the Dordrecht facility shipped at least some of what Dutch officials describe as fluoroether waste to a chemical plant owned by Miteni in Trissino, Italy, for reclamation. The Miteni factory is under investigation in connection with PFAS pollution in Italy’s Veneto region. HFPO-DA was found in wells near the Miteni facility last year, the Regional Council of Veneto says.

Chemours no longer ships the fluoroether material to Miteni. The Italian facility shut down on Oct. 31, 2018, leaving its 121 employees out of work, according to the European Monitoring Centre on Change. An Italian court declared the company bankrupt in November 2018.

Now, the status of the HFPO-DA generated at the Dordrecht plant is in flux. Complicating the situation further is material piled up at the shuttered Miteni facility.

“The recent bankruptcy of our European recycling contractor requires us to take responsible actions to ensure we continue to recycle the vast majority of [HFPO-DA],” Chemours says in its Jan. 25 statement.

Chemours is asking Dutch authorities to allow the Dordrecht plant to accept and store for one year as much as 15 metric tons of HFPO-DA material from the Miteni site. That’s according to a Feb. 7 document from South Holland, the province that includes Dordrecht. The Dordrecht facility is seeking permission for temporary storage, the document says, because “Chemours in the United States does not yet have a permit to receive and process this waste stream.”

Meanwhile, Chemours says in its statement that it is asking the US EPA to allow the company to ship to North Carolina the unprocessed material that its Dordrecht plant sent to Miteni before the Italian firm’s bankruptcy.

For its part, the EPA asked Dutch regulators in December to temporarily stop the Dordrecht plant from sending fluoroether waste to Fayetteville Works, according to an agency document that surfaced in January and was first reported by the news site NC Policy Watch. The EPA asked the Dutch about the chemical makeup of the material shipped from the Dordrecht factory. It also sought details about “management of the wastes.” The EPA tells C&EN it has not yet received this information from the Dutch or Chemours. The temporary halt on US imports of the material will remain until the EPA gets the data, reviews the information, and makes a regulatory determination, the agency says.

Randall, the Chemours spokesperson, takes issue with the characterization of the HFPO-DA material as waste. “The Fayetteville Works site does not receive wastewater from any other Chemours facilities,” she says.

Under US law, if the material isn’t technically waste, the Fayetteville facility doesn’t need a permit to process the HFPO-DA material into GenX. The EPA tells C&EN that on the basis of information previously submitted by Chemours, the recovered material would not meet the US definition of hazardous waste.

EPA documents indicate that Chemours makes GenX from reclaimed HFPO-DA under the federal law governing the manufacture of commercial chemicals, the Toxic Substances Control Act (TSCA). In doing so, it must adhere to a TSCA order in which the EPA set conditions for the production of virgin GenX, notably that Chemours must prevent fluoroether releases into the water and air. At the end of the process making GenX from HFPO-DA, the Fayetteville plant sends wastewater to licensed incinerators in Texas and Arkansas, says Randall, the Chemours spokesperson.

Chemours apparently did not inform the EPA about the amounts of GenX it made from imported, reclaimed HFPO-DA, as required, until after a 2017 inspection by the agency. The EPA cited the company on Feb. 14 for failing to report its annual production of GenX sourced from the material imported from the Netherlands. Chemours has since corrected this paperwork error, EPA enforcement documents indicate.

While the disposition of Chemours’s reclaimed HFPO-DA in Europe remains pending, Dutch officials are raising red flags about potential releases of the chemical during transportation for recycling. In response to a request from the Netherlands House of Representatives, the nation’s Human Environment and Transport Inspectorate examined how the Dordrecht plant characterizes and handles its waste streams, issuing a report in July.

Chemours has not systematically identified which of its waste flows contain fluoroethers, the report found. “Chemours takes no measurements to determine whether [GenX-related] substances are in the waste” it ships, the report says. “The investigation showed that little or no attention is given to [fluoroether] substances in waste throughout the entire chain” of waste handling. As a result, HFPO-DA and its chemical cousins were released into the environment at “various places” as the waste was hauled, the report says.

In addition, businesses that transport wastewater from the Dordrecht plant to waste processors don’t regularly clean the tankers they use and don’t test for residual fluorocarbons in these vessels, the report adds. This may have led to subsequent contamination with fluoroethers of other wastes hauled in the tankers. And fluoroethers may have ended up in sanitary sewers when tankers were rinsed out, the report says.

Dutch officials are suggesting that the European Union tighten regulation of GenX and reclaimed HFPO-DA. The Netherlands National Institute for Public Health and the Environment in November sent a risk-management analysis for GenX to the European Chemicals Agency.

“The unpredictable, wide spread and uncontrollable emissions” of HFPO-DA during the transportation and treatment of GenX-related waste “are no longer manageable in an efficient way,” the analysis suggests. “Regulatory measures should preferably be aimed at the production and use phase and should prevent a situation in which HFPO-DA containing waste cannot be traced and treated responsibly.”

The Dutch agency’s analysis also raises the possibility of a need for global controls on GenX and any other substances that form HFPO-DA. It suggests the world could take action against these fluoroethers under the Stockholm convention, a global treaty that restricts or bans persistent organic pollutants.

Ironically, GenX, which came to market in 2009, was developed as a “more sustainable” substitute for perfluorooctanoic acid, a toxic, persistent, and bioaccumulative chemical that is a candidate for control under the Stockholm convention. If GenX eventually ends up governed by the Stockholm convention—as its predecessor is likely to be—Chemours will be searching for another substitute to aid in the manufacture of fluoropolymers to coat nonstick pans and make industrial membranes.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter