Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Recycling

Sunlight powers chemical recycling of polyethylene terephthalate

A composite converts light into heat that drives chemical breakdown of PET into monomers

by Prachi Patel, special to C&EN

March 19, 2022

| A version of this story appeared in

Volume 100, Issue 10

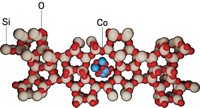

Catalytic processes to chemically break down polyethylene terephthalate (PET) typically require high temperatures that consume a lot of energy. Researchers have now designed a system that uses sunlight to drive the catalytic breakdown of this common plastic into valuable monomers (Matter 2022, DOI: 10.1016/j.matt.2022.02.002). The solar method should save 3.7 gigajoules of energy and 0.4 metric ton of carbon emissions for each ton of recycled PET compared with conventional catalytic methods, Soochow University chemist Jinxing Chen says. For their solar-driven upcycling method, Chen and his colleagues relied on two photothermal materials—carbon nanotubes and polydopamine—which absorb sunlight to produce heat locally. The researchers coated the nanotubes with polydopamine, then suspended them in ethylene glycol along with an ionic liquid catalyst. They added flakes of PET to this mix and placed it in the sun, which caused the photothermal composite to heat up to 150 °C. This heat and the catalyst triggered the ethylene glycol to break ester linkages in PET, producing high-purity bis(2-hydroxyethyl) terephthalate (BHET) powder. Higher light intensity and exposure time boosted yields. The researchers repolymerized the monomers into PET. This process can break down PET that has been dyed or blended with another polymer.

CORRECTION:

This article was updated on March 22, 2022, to correct the headline. The polymer being recycled is polyethylene terephthalate, not polyethylene.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter