Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

3-D Printing

Speeding up 3-D printing

A new printing method is inspired by medical imaging

by Katherine Bourzac

February 4, 2019

| A version of this story appeared in

Volume 97, Issue 5

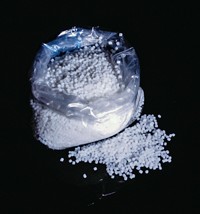

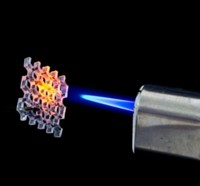

A new 3-D printing method uses simple hardware and sophisticated imaging software inspired by computed tomography (CT) scans to rapidly generate complex objects (Science 2019, DOI: 10.1126/science.aau7114). The method produces objects with very smooth surfaces and could be used to mass customize ergonomic tools and furniture or make optical components. “Most current 3-D printers build up components layer by layer,” says Hayden Taylor, a mechanical engineer at the University of California, Berkeley, whose group developed the new method in partnership with the lab of Christopher Spadaccini of the Lawrence Livermore National Laboratory. The standard approach can be slow, and it produces parts that are rough and mechanically weak. Taylor and Spadaccini wanted to print the entire volume of an object at once. They were inspired by the 3-D imaging used to make CT scans. The medical imaging technique rotates a scanner around a patient’s body and constructs a 3-D image from reflected X-rays. The new printing method does this in reverse. The researchers developed software to turn a 3-D design into a light field that’s projected into a rotating vat of photocurable materials. When the vat completes its rotation after 30 s to 5 min, the object is printed. This can be done using an off-the-shelf movie projector. Because the object is not printed on any kind of support, and does not move relative to the vat, it’s possible to print using even very viscous or fragile materials, such as hydrogels. And this technique, unlike most 3-D printing methods, can be used to “overprint” customized parts around an existing object, such as a personalized handle around a metal screwdriver blade.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter