Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Bees’ legs inspire high-volume drug patches

A material covered in tiny hair-like structures can trap large amounts of drug particles

by Alla Katsnelson, special to C&EN

March 8, 2019

A microfabricated material inspired by the hairs covering bees’ legs may one day be used to make skin patches that release medicine at five times the volume of commercially available patches (Proc. Natl. Acad. Sci. U. S. A.2019, DOI: 10.1073/pnas.1813336116). The material could also be used to dose plants with pesticides or release substances that mop up pollutants, the researchers say.

João Mano, a chemist at the University of Aveiro, was initially exploring the possibility of creating nanoparticles based on the structure of pollen. In looking up images of pollen, he encountered close-ups of bees carrying impressive quantities of the stuff jammed into the spaces between the hairs in the fuzz covering a honey bee’s body. He was particularly drawn to the structure of the insects’ leg hairs, which are long, stiff and thin. “We realized that the distance between the hairs is similar to the size of the pollen grains,” says Mano. “This profile had a very nice ability to mechanically fix the granules.”

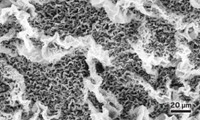

He and his colleagues used soft lithography to manufacture a series of microstructures out of polydimethylsiloxane (PDMS), a widely used elastomeric material. They created 54 versions of the bee-inspired material, adorning it with pillars that modeled the hairs, to analyze how several parameters—the distance between the pillars, their height, their stiffness, and the size of the particles—affect how many particles it could carry. To load the material, they simply pressed it into a plate of particles.

As they predicted, the patches could carry more material when the distance between the pillars matched the particle size—ideally, 80 micrometers for both. Material stiffness and pillar height were also important. The material was most effective when the pillars were 300 micrometers long and moderately flexible. In a trial run, patches of the material held large amounts of the antibiotic tetracycline that, when placed on a petri dish, killed bacteria.

The patches carried about 25 mg of particles per cm2—significantly higher loads than smoking-cessation, analgesic, and other skin patches approved by the US Food and Drug Administration. This high loading could be an advantage for delivering large amounts of anti-inflammatory or antibiotic drugs, or for agricultural or environmental applications, Mano says.

The bee-inspired design is novel, and “pushes the limit of [particle] fixation to a new high,” says Melik C. Demirel, an engineer and materials scientist at Pennsylvania State University.

Mano says the next step is to remake the micromaterial using biodegradable polymers or hydrogels. PDMS is versatile and easy to work with as a proof of concept, “but we want to make the membrane from a material that could be put inside the body or would degrade with time” in the environment.

CORRECTION:

This story was updated on March 13, 2019, to correct the spelling of João Mano's name in the last paragraph.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter