Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biomaterials

Lightweight but strong ‘wood armor’ can fend off bullets

Inspired by a fish’s natural defense to piranhas, layered lignocellulose creates a rugged material

by Alla Katsnelson, special to C&EN

May 26, 2022

Whether it’s fuel for fires, timber for building, or those flat white sheets we write on, we humans have made many uses of wood. Now, researchers have taken wood fibers and sandwiched a soft polymer between them to make a superstrong armor, unyielding enough to defend against whopping impacts but pliant enough not to shatter on strong contact (ACS Nano 2022, DOI: 10.1021/acsnano.1c10725). The armor is also much lighter than synthetic impact-resistant materials currently available, the researchers say.

Huiqiao Li, a materials scientist at Huazhong University of Science and Technology who led the work, says the wood armor was inspired by the pirarucu, a carnivorous, bonytongue fish from the Amazon River basin. Its hard outer skin has “an intriguing resistance to cracking” and “can often defend [the animal] against the spear-like, long teeth of the piranha,” Li says. The fish’s scales get their toughness from a rigid, mineralized outer side combined with a soft but tough inner side of slightly unaligned layers of collagen fibers.

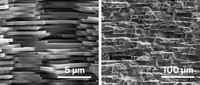

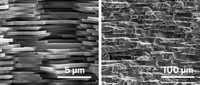

To create the material, they made a stacked structure of alternating sheets of lignocellulose—an abundant and renewable substance from the cell walls of woody plants—and a cross-linked siloxane polymer. Lignocellulose has secondary hydrogen bonds that can be reformed once they are broken, which makes the material strong while minimizing the risk of fracture, Li says. And the polymer layers are normally soft but become tougher when compressed by an impact.

During fabrication, the fibers in each lignocellulose layer are brushed in slightly different directions relative to the layers below and above it, creating the same stratified and unaligned arrangement from which pirarucu scales derive their damage tolerance. Ballistic tests showed that a bullet from a 9 mm revolver left just a small dent in the armor. The material is one-sixth the density of steel, so Li and his colleagues envision using it to fortify cars and buildings.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter