Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biomaterials

New 3D-printed muscle is the strong, sensitive type

LED-embedded liquid crystal elastomers enable optical feedback

by Emily Harwitz

July 26, 2021

| A version of this story appeared in

Volume 99, Issue 27

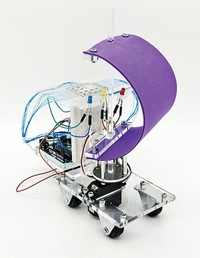

One of the biggest challenges in soft robotics is getting a robot to move without rigid motors or hard circuitry that restrict the robot’s range of motion. Liquid crystal elastomers (LCE) are powerful and promising polymers that are known to bend or shrink in response to heat and that can serve as artificial muscles, also called actuators. Now a team of researchers led by Shuo Li at Cornell University has taken LCE artificial muscles a step further by developing a way to 3D print a soft actuator that can not only crawl, grab things, and lift heavy weights, but also provide feedback on those actions, opening the door for a more controllable soft robot (Sci. Adv. 2021, DOI: 10.1126/sciadv.abg3677). The team used digital light processing, a 3D-printing technique, to fabricate the muscle layer by layer and embed light-emitting diodes (LEDs). The material bends when part of it is heated, and the polymer chains at that point realign, which changes the material’s opacity. The more the material bends, the more transparent it becomes. Embedded photodiodes detect this change in transparency, providing feedback about the material’s motion that a robot could use to plan its next move. Being able to self-sense “is something that’s very new in materials,” says Chiara Daraio, a materials scientist at the California Institute of Technology not involved with the research. “I think it’s very neat.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter