Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biomaterials

Silk succumbs to heat processing

Method transforms regenerated silk protein into moldable material

by Bethany Halford

January 3, 2020

| A version of this story appeared in

Volume 98, Issue 1

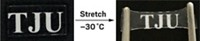

The silk fibroin protein that silkworms spin into cocoons is prized for its mechanical properties. But the complex network of hydrogen-bonded β-sheets that give silk its strength and flexibility also make it difficult to process with heat. Silk will burn rather than melt. To make materials from silk protein, scientists have used solution-processing methods, but these require large amounts of solvent and the silk protein tends to recrystallize in solution over time. Now, researchers led by Tufts University’s Chunmei Li and David L. Kaplan have figured out a way to turn silk protein into solid pellets that melt like plastic (Nat. Mater. 2019, DOI: 10.1038/s41563-019-0560-8). The researchers make the tiny pellets by freeze-drying an aqueous solution of silk fibroin. They then melt the pellets by heating them under pressure so that they fuse into larger pieces of material. Bulk solids made from these pellets can be machined into medical devices, like bone screws and ear tubes, that are biocompatible, biodegradable, and can be loaded with bioactive molecules, such as enzymes and drugs. Unlike silk fibroin solutions, the pellets can be stored over long periods and shipped to manufacturers.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter