Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Coatings

‘Green’ coating protects plastics

Transparent film of nanocellulose in a glass matrix confers hardness and fracture toughness to plastic

by Mitch Jacoby

June 14, 2018

| A version of this story appeared in

Volume 96, Issue 25

Devices that can flex and stretch, including wearable electronics, roll-up solar cells, and foldable displays, are all the rage these days. Engineers design those devices to keep working, bend after bend. A tough, transparent, eco-friendly coating applied to the plastic support might help those devices last even longer, a study suggests (ACS Nano 2018, DOI: 10.1021/acsnano.8b01057).

Many plastic devices have thin coatings designed to go unnoticed. Measuring just a fraction of a micrometer in thickness, these nearly invisible films of organic and inorganic materials improve a wide range of commercial products. For example, polysiloxane coatings on polycarbonate eyeglass lenses make them scratch resistant.

Knowing that manufacturers are always on the lookout for new types of cost-effective coatings, a team led by Stanford University materials scientists Farhan Ansari and Reinhold H. Dauskardt looked to an unusual place for source material—the forest.

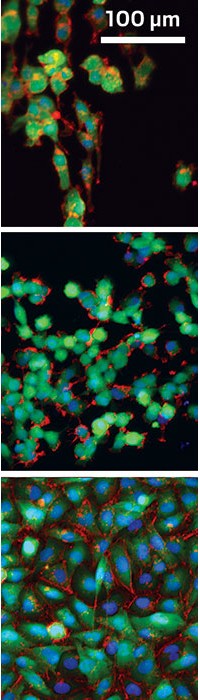

The team made hybrid coatings by embedding various concentrations of nanocellulose fibrils, a tough material derived from trees, in a glass matrix composed of zirconium alkoxide and an epoxy-functionalized silane. The team used low-cost colloidal chemistry methods to prepare the precursor solutions and then sprayed the mixtures onto flexible polymer substrates, including poly(ether imide) and poly(ethylene terephthalate), and then cured the films at low temperature. The results were highly transparent, nanometer-thick films.

Tests indicate that coatings containing 20 wt % nanocellulose protect the polymer substrates by boosting hardness and fracture resistance. Microscopy analysis shows that even after 20,000 bending cycles, the films revealed no signs of delamination or cracking.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter