Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Coatings

Smudge-proof, bendable coating resists scratches

Omniphobic composite material combines glass’s wear resistance with plastic’s flexibility

by Bethany Halford

July 26, 2019

| A version of this story appeared in

Volume 97, Issue 30

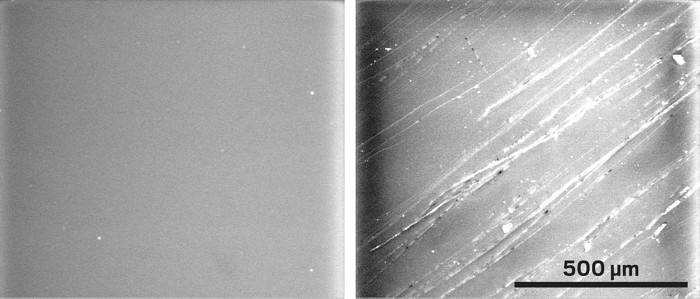

Keys and dust particles can easily scratch up smartphone screens. But a new coating could make such abrasive actions inconsequential. Chemists in Guojun Liu’s lab at Queen’s University in Ontario have created a transparent composite coating that remains scratch-free when it is scraped with steel wool 20 times (Angew. Chem., Int. Ed. 2019, DOI: 10.1002/anie.201904210). When cast on a plastic film, the material also bends up to 500 times without apparent damage and resists smudges. Liu’s team created the coating by cross-linking octa(3-glycidyloxypropyl) polyhedral oliogomeric silsesquioxanes (GPOSS) via ring-opening polymerization of GPOSS’s epoxides. GPOSS’s silica core gives the material its hardness; the glycidyloxypropyl network bestows flexibility. The chemists also incorporated poly(dimethylsiloxane) into the composite. This low-surface-tension liquid lubricant makes the coating omniphobic, meaning it repels both oil- and water-based contaminants. Liu says this is the first material that’s wear resistant, flexible, transparent, and omniphobic. Plus, he says, it’s easy to make. Liu says that in addition to potentially being a protective coating for displays, the composite could be used for automobile bodies and windshields, if it doesn’t degrade when exposed to sunlight for extended periods.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter