Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Electronic Materials

Movers And Shakers

Zhenan Bao makes stretchable electronics for artificial skin

Stanford professor envisions semiconducting polymers with integrated sensors to coat robots or prostheses

by Neil Savage, special to C&EN

August 18, 2020

| A version of this story appeared in

Volume 98, Issue 32

Zhenan Bao of Stanford University is the first recipient of the ACS Central Science Disruptors and Innovators Prize, which highlights a paradigm-shifting scientific breakthrough of broad relevance (ACS also publishes C&EN). Bao, a chemical engineer, received the award for her “extensive and disruptive research in the field of conducting polymer molecular designs and their applications, as well as her outstanding advances in the development of artificial electronic skin and other bioelectronic devices.” Bao’s work in this area includes the development of stretchable circuits, flexible batteries, and a material that connects medical implants to biological tissue. These stretchable electronics allow Bao to build devices that can interface with living tissue. Such electronic skin could also be used for both human prostheses and robots.

Bao immigrated to the US from China as an undergraduate and spent her first years after earning her PhD working on flexible displays at Bell Labs. She joined the faculty at Stanford University in 2004. Neil Savage spoke with Bao about her work on electronic skin and all that it touches. This interview was edited for length and clarity.

Vitals

▸ Education: chemistry major, Nanjing University and University of Illinois, 1991; MS, chemistry, 1993, and PhD, chemistry, 1995, University of Chicago

▸ Favorite material to work with: Polymers. My kids love to play with slime. I always tell them the slime my group makes can be used to make artificial electronic skin for prostheses or make batteries for future electrical vehicles last longer.

▸ Favorite science fiction:X-Men Origins: Wolverine was an inspiration for our self-healing electronic skin.

▸ Science hero: George Whitesides

▸ Hobbies: I enjoy gardening and growing orchids. Orchids are very sensitive to how you water them. It feels very satisfying seeing healthy and well-hydrated orchid roots, as it took me years to find the right conditions. This was like running a very slow “reaction” to see results.

What drives your group’s work?

We are trying to change the future of electronics. Today’s electronics are rigid and brittle. We envision a future where the electronics are merged into what we wear and what we attach to our bodies or what we implant inside our bodies. As a chemist by training, I’m most excited about understanding molecular design for this new generation of electronics.

How did you come to focus on electronic skin?

When I started at Bell Labs two decades ago, my dream was to make foldable displays. After I moved to Stanford, I wanted to work on something further out. A colleague in mechanical engineering was building a robotic cockroach that could climb up a wall. But once the cockroach got to the top of the wall, it would fall down because it didn’t have sensory feedback. That’s when I got intrigued with sensors that can sense touch. I thought that would be a great place where we could apply expertise from flexible electronics and potentially learn from biological systems.

We started by mimicking the sense of touch of human skin, and that led us to start thinking about all the properties of human skin such as stretchability, biodegradability, and self-healing properties. So we decided to use human skin as the inspiration to define the properties and functions for the electronics we would design and build.

How do you make electronic skin?

We work with polymer-based electronic materials because they can be designed to have all these skin-like properties. For polymers to be able to transport electrons or electron holes effectively, the conventional wisdom has been that they need to have rigid, crystalline structures. However, for stretchable electronics, we need to have a large fraction of amorphous domains blended with a small fraction of crystalline domains. So we had to come up with new ideas for designing semiconductors so that we do not compromise one property for another—basically to have high charge-carrier mobility while still being able to reversibly elongate the material by at least twice its original length.

How do you build semiconductors that have the properties you need?

One concept we introduced is to incorporate dynamic chemical bonds into the polymer semiconductor. These dynamic bonds may be weak hydrogen bonds or weak metal–ligand bonds that can easily break under strain and reconnect after strain is removed. If covalent bonds are broken when the polymers are stretched, they cannot readily be reconnected at room temperature, so the material is permanently damaged. But if dynamic bonds are broken during stretching, they provide a place to use up the mechanical energy instead of breaking the covalent bonds. In the end, the polymer is able to go back to its original state after the strain is removed, and these dynamic bonds can be reconnected. Dynamic bonds have been used before in other applications. Our challenge was to come up with molecular designs that can provide good charge transport at the same time.

We also discovered that when thin films of semiconducting polymers are made into nanostructures, the result is much more ductile than the bulk polymer. So, we developed ways to form polymer semiconductor nanofibers from a properly chosen polymer blend. As a result, we now have a number of stretchy, high-performance semiconducting polymers that were originally fragile and brittle.

To build a circuit, we also need a dielectric layer, we need conductive materials, and all of these components need to be stretchable. We needed to develop those materials, again adding new functionalities without compromising electronic properties. In addition, we needed to develop a patterning process to create patches of each type of material so we can build circuits. We now can make thousands of transistors at a time, and the functional circuit block we built has tens of transistors in it.

Will electronic skin actually reproduce the sensation of touch?

Touch sensation is generated through a combination of signals from many mechanoreceptors of several types. We are trying to make the electronic skin sensors’ output similar to what skin’s mechanoreceptors would generate. We have sensors that sense, say, pressure or strain or sheer force, and we also have the circuit that converts these signals into electrical pulses. Pulsed electrical signals are basically what biological mechanoreceptors would generate. We hope our electronic skin will produce the sensation of touch when its electrical pulses are used to stimulate nerves. But this is yet to be tested, and the electronic skins we build now still do not have the number of sensors and signal processing ability to match the complexity of human skin. We’re getting close to being able to integrate a number of different types of sensors onto the electronic skin, and they all generate a nerve-like signal.

Our vision is to eventually build electronics that directly communicate with living systems. To help people with prostheses to regain their sense of touch would have a great impact.

How far in the future is this kind of electronic skin?

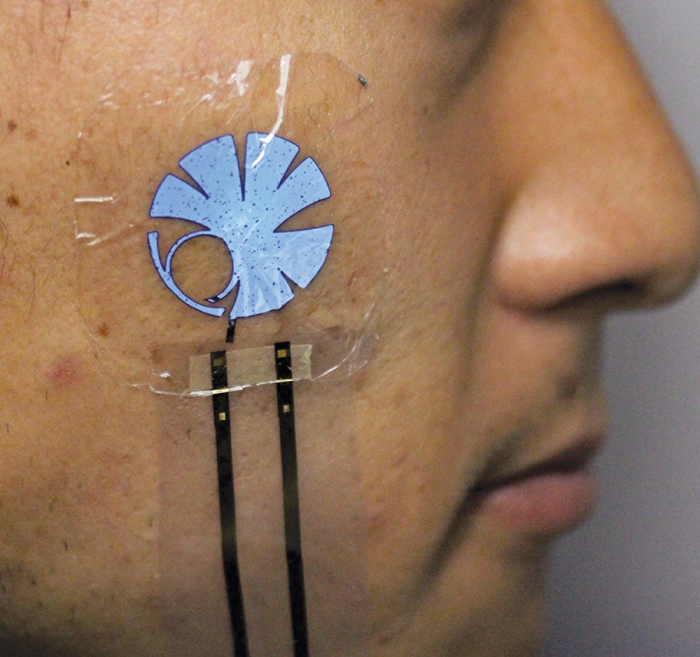

That’s the longer-term vision, but in the short term, the sensors that we have developed have led to noninvasive, continuous-monitoring wearable devices. For example, blood pressure monitoring devices became a spinoff company (PyrAmes). We’re developing other wearable sensors that could sense the stress level of a person through monitoring chemicals from sweat or from saliva. These sensors combined with circuits can potentially be used as robotic skin to allow robots to work with humans safely.

Neil Savage is a freelance writer. A version of this story first appeared in ACS Central Science: cenm.ag/bao.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter