Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Electronic Materials

This multilayer film constricts under an electric field

The new material gets its electrostrictive properties from stress-inducing interactions between metal oxides

by Ariana Remmel

September 22, 2022

| A version of this story appeared in

Volume 100, Issue 34

Researchers have discovered a new way to engineer thin films that change volume under an electric field. Their technique could help scientists create small, energy-efficient biomedical devices (Nature 2022, DOI: 10.1038/s41586-022-05073-6).

Electrostrictive materials generate strain in response to an electric field. Researchers are interested in harnessing this property, measured by a material’s electrostriction coefficient, to build low-power biomedical devices such as microsensors. But many of the highest-performing electrostrictors contain lead, which can be toxic. Recently, scientists discovered electrostriction properties in gadolinium-doped cerium oxide (CGO), which is used in solid oxide fuel cells. Materials scientists Haiwu Zhang, Nini Pryds, and Vincenzo Esposito of the Technical University of Denmark wanted to know if they could improve its performance.

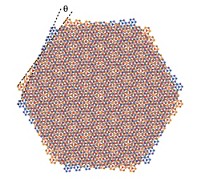

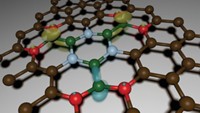

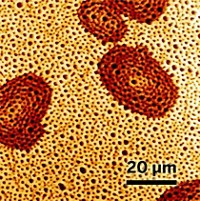

They started by depositing alternating layers of CGO and erbium-stabilized bismuth oxide onto a neodymium gallate substrate, making multilayer films about 17 nm thick. Chemical defects in the oxide layers create local lattice distortions in the form of dipole moments that exert strain when oriented to an electric current. At each interface, stress generated from the lattice mismatch between oxides shifts the dipoles into partial alignment. The researchers then apply voltage to elongate the film by fully aligning the dipoles (shown).

Increasing the number of interfaces allowed the team to make films with electrostriction coefficients 1,000 times as high as commercial lead-based electrostrictors, they say.

“The effect of the interface on electrostriction is surprisingly large,” says Shujun Zhang, a materials scientist at the University of Wollongong who was not involved in the study. It’s a discovery that could benefit the design of future electrostrictors, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter