Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Novel material outperforms standard catalysts in zinc-air batteries

Thin sheets of a trimetallic nitride allow Zn-air battery fibers to perform efficiently even when twisted

by Lakshmi Supriya, special to C&EN

June 11, 2020

| A version of this story appeared in

Volume 98, Issue 23

Using thin sheets of a new trimetallic material as catalysts in zinc-air batteries enhances the batteries’ performance, increasing their energy density (Nano Lett. 2020, DOI: 10.1021/acs.nanolett.0c00717). Made of three common metals—nickel, iron, and manganese—the new material could be an alternative to precious-metal catalysts, making Zn-air batteries less expensive and thus allowing them to be used more widely. What’s more, the material retains its performance even when the battery, shaped into a fiber, is twisted.

“Our work may open a completely new paradigm of devising efficient electrocatalysts for various metal-air batteries,” says study coauthor Guoxiu Wang of the University of Technology Sydney. They could also be used in fuels cells and in reactions that split water to generate hydrogen, the authors say.

Zn-air batteries use a constant flow of oxygen from the air to oxidize a zinc electrode and generate current. During charging, the reverse happens: zinc is reduced, and oxygen is generated. The batteries have the potential to store energy at high density and are environmentally friendly, making them potentially useful in applications such as electric vehicles.

The batteries also contain catalysts to help increase the efficiency of the reactions involving oxygen. But it’s rare to find catalysts that can efficiently boost both the reduction of oxygen during discharge and the evolution of oxygen during charging.

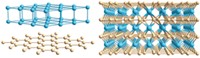

Transition-metal nitrides are promising catalysts in metal-air batteries because they have high electrical conductivity and form different complexes easily. Nickel, iron, and manganese nitrides have shown good performance in catalyzing the oxygen evolution reaction, though their oxygen reduction rates are poor. Wang, Fengxia Geng of Soochow University, and colleagues speculated that a nitride made with the three metals should have better performance. Making such a trimetallic nitride into thin sheets would allow exposure of surface atoms and unsaturated coordination sites, greatly improving the oxygen reduction reaction.

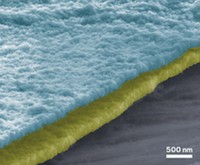

But making thin sheets of NiFeMn nitride is next to impossible because the compound tends to form thick clumps. So to make stable sheets of the compound, the researchers mixed a titanium carbide (Ti3C2) and NiFeMn hydroxide. The two oppositely charged materials self-assembled to form a monolayer of hydroxide on a sheet of Ti3C2. Annealing in an ammonia atmosphere transformed the hydroxide into the nitride.

“The authors innovatively demonstrated a new method to well address the two problems simultaneously,” says Chunyi Zhi of the City University of Hong Kong who studies energy storage materials and was not part of the study.

The researchers then made a Zn-air battery using the new catalyst, which showed an energy density of 693 (W h)/kg, compared with about 550 (W h)/kg for Zn-air batteries today, and had good stability for 120 charge-discharge cycles. Compared with this, a standard platinum and ruthenium–based catalyst showed a large voltage gap between the charge and discharge curves, indicating poor stability, even at 60 cycles.

In addition, the thin sheets allowed the team to make a Zn-air battery in the form of fibers. The battery showed equally good performance when the fibers were twisted or bent. Three such fibers connected together powered light-emitting diodes and an electroluminescent panel, opening up possibilities for use in flexible electronics.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter