Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Metal-Organic Frameworks

Molecular motors join forces in a metal-organic framework

Crystalline scaffold helps to organize tiny machines

by Mark Peplow, special to C&EN

March 18, 2019

Molecular machines can already act as switches, shuttles, motors, or pumps, but most only work in solution, where it’s difficult to coordinate their activity. To help the minute gadgets perform useful work at everyday scales, chemists need to find ways to marshal their efforts.

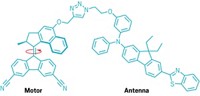

Now a team led by Ben L. Feringa at the University of Groningen has built propeller-like molecular motors into the structure of a metal-organic framework (MOF) to create organized arrays. MOFs are molecular scaffolds containing metal-based nodes connected by organic-molecule struts, forming an extremely porous crystalline lattice. Feringa’s moto-MOFs contain about 3 x 1020 motor units per cubic centimeter of material. All of them turn in the same direction when exposed to ultraviolet light (Nat. Nanotechnol. 2019, DOI: 10.1038/s41565-019-0401-6).

“It’s terrific, it’s quite an achievement,” says Stephen J. Loeb, a molecular machinist at the University of Windsor who was not involved in the research.

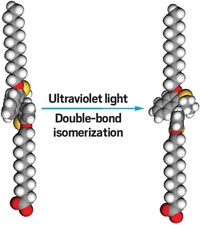

The system relies on a type of molecular motor Feringa has worked on for the past two decades, a design that helped snag him a share of the 2016 Nobel Prize in Chemistry. The motor contains two flat molecular paddles connected by a carbon-carbon double bond. The movement of the paddles is spurred by applying light and heat. Ultraviolet light forces the paddles to rotate out of their shared plane; a little warmth then helps one paddle tuck behind the other to stop it returning to its original position. Repeating this light-heat sequence makes the paddles complete a full 360-degree revolution.

The Groningen team tested their two-stroke molecular motors in solution, using various spectroscopic techniques to watch how they rotated. Then the researchers made a zinc-based MOF, and replaced some of its struts with motor molecules. Raman spectroscopy revealed that the motors behaved just as they did in solution, making a full revolution in about 25 minutes—a deliberately slow pace that allowed the team to follow the action in detail. “Being able to organize these in a framework, and show that it works essentially the same as in solution, is fantastic,” Loeb says.

Still, the motors do not necessarily start at the same point in their cycle, so the motion is not yet fully coordinated. “It’s not a coherent machine, where everything is moving in sync,” says Groningen’s Wesley R. Browne, who led the spectroscopy work. “That’s the next challenge.” Such moto-MOFs might eventually be used to control the diffusion of gases, or even pump reagents over catalysts embedded in the MOF. But that’s a long way off. For now, the researchers hope to use polarized light to line up the motors so that they can turn in unison, and they are also working on thin-film MOFs that allow ultraviolet light to reach the motors more easily.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter