Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Nanomaterials

Chemists find simple route to uncommon nanocatalyst shapes

Vapor-phase method yields metal tetrahexahedrons that boost catalytic activity

by Mitch Jacoby

September 12, 2019

| A version of this story appeared in

Volume 97, Issue 36

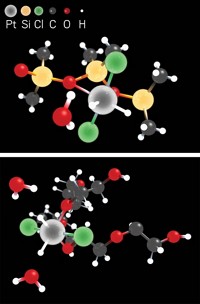

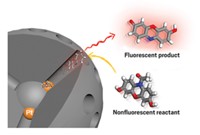

A simple vapor-phase process converts common metal precursors to unusually shaped, catalytically active metal nanocrystals that are difficult to produce via other methods. The procedure, which was used for making single-metal and bimetallic nanocrystals, may provide a low-cost route to catalysts for fuel cells and other applications (Science 2019: DOI: 10.1126/science.aax5843).

The catalytic activity of one face of a crystal may be different from that of other faces, a result of each face’s unique geometry and electronic properties. Thermodynamics favors the most stable faces. But because those may not be the most catalytically active ones, chemists often rely on organic capping ligands to stabilize specific faces and guide crystals to grow in a desired shape. The ligands, however, can block active sites and must be removed, complicating the process and sometimes adversely altering the crystals.

Northwestern University’s Liliang Huang, Chad A. Mirkin, and coworkers have come up with a way to sidestep the ligand problem. The team heated precursors of platinum, palladium, and other metals in a tube furnace in the presence of volatile dopants such as bismuth. The dopants guided the crystal-growth process to produce gram quantities of nanosized tetrahexahedrons—24-sided crystals with catalytically active faces known as (210) facets. The dopants, which lower the surface energy of the (210) facets during crystal growth, evaporate from the crystals as they grow. Crystals with these facets are uncommon and are typically made via complex methods in tiny quantities.

With this method, the team boosted the performance of a commercial platinum fuel-cell catalyst by a factor of 20.

Nanomaterials experts Catherine J. Murphy of the University of Illinois at Urbana-Champaign and Younan Xia of the Georgia Institute of Technology describe the work as interesting and important. Murphy notes the method may work to refresh catalysts that have become inactive after extended use. And Xia emphasizes the method’s potential for lowering catalyst preparation costs.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter