Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Automating synthesis from planning to execution

With a little human help, artificial intelligence and a robot make drug molecules

by Sam Lemonick

August 8, 2019

| A version of this story appeared in

Volume 97, Issue 32

A new system uses artificial intelligence and robotics to carry out almost all the steps of chemical synthesis, from planning to execution, with just a little bit of human help (Science 2019, DOI: 10.1126/science.aax1566). Timothy F. Jamison, Klavs F. Jensen, and colleagues at the Massachusetts Institute of Technology demonstrated the system could synthesize several drug molecules and two small compound libraries.

The MIT team, which included chemists, computer scientists, and chemical and mechanical engineers, drew on progress in two related areas: algorithmic prediction of reactions and automated lab equipment. Chemical synthesis has progressed from art to science over the centuries. Twentieth-century chemists like Robert B. Woodward and Elias J. Corey helped develop the logical underpinnings of synthesis planning, and advances in computer science have allowed humans to teach these rules to artificial intelligence algorithms, enabling them to plan chemical routes to target molecules. Concurrent progress in robotics and process chemistry similarly allow autonomous systems to follow directions and carry out multistep syntheses.

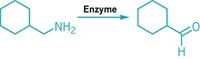

The MIT researchers trained artificial intelligence algorithms on reactions drawn from US patents and the Reaxys database. Their synthesis planner uses those algorithms to propose synthetic routes, including reaction conditions, to a given molecule and to evaluate which path is best in terms of the number of steps and predicted yield.

On the other side of the system, a robotic arm sets up experiments by connecting tubes supplying different reagents to flow-chemistry modules like reactors and membrane-based separators. Other groups have demonstrated batch-chemistry-based automation systems, but Jamison says flow chemistry was better suited to automation for the types of reactions they were trying to do. It also enabled them to run reactions at higher temperatures and pressures. The team’s robot could synthesize compounds such as aspirin with a 91% yield and (S)-warfarin with a 78% yield and a 4.1:1 enantiomeric ratio. It also synthesized two libraries of five drug-related compounds each.

Although other researchers have developed AI synthesis planners or automated synthesizers, the MIT group’s system comes closest to a fully automated system. “I have little doubt that this concept will dramatically accelerate synthetic design and will change the way we do synthesis. It is truly game changing,” Cathleen Crudden, an organic chemist at Queen’s University in Ontario, says.

Human chemists do play a role in the group’s system. They edit the recipe generated by the AI before it’s fed to the robotic chemist. “We still need a chemist to fill in the details” of precise concentrations, temperatures, and timing, says coauthor Connor Coley, lead developer of the system’s software. Jensen says the papers and patents that their AI learned from didn’t always include this information at the level of detail their algorithms need. But Coley says there’s no reason an algorithm couldn’t do this step as well if it had the right data.

The group doesn’t want to replace human chemists. “The aim here is not to eliminate the chemist,” Jensen says, but to give chemists more time for creativity by automating routine synthetic tasks.

Paul Richardson of Pfizer, who has explored automation, notes that past attempts at automating synthesis haven’t yielded much return on investment but says this system is an exciting advance. And he appreciates the researchers’ reliance on humans, adding, “It is refreshing to see the authors acknowledge the limitations of utilizing computational predictions as well as the need in some cases for expert human intervention.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter