Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Catalysis

Chemists stabilize single-atom catalyst in liquid

Weakly pinned by ligands, platinum atoms exhibit high activity and resist aggregating into nanoparticles

by Mitch Jacoby

March 14, 2019

| A version of this story appeared in

Volume 97, Issue 11

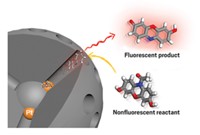

By gently confining individual metal atoms in a surfactant solution, researchers have come up with a highly active and chemically selective catalyst that combines the advantages of conventional solid-state and liquid-phase catalysts (Nat. Commun. 2019, DOI: 10.1038/s41467-019-08804-y).

To maximize the use of costly platinum and other noble metals, researchers have recently devised a handful of methods for isolating individual catalytic atoms, typically on solids. In addition to using resources efficiently, the molecular uniformity of single-atom catalysts (SACs) simplifies the job of deducing reaction mechanisms, a key to improving catalyst performance. This uniformity is a hallmark of liquid-phase molecular catalysts but atypical of solid catalysts, which lack isolated metal atoms. But there are relatively few methods for making SACs, and metal atoms in liquid catalysts don’t always stay put. Instead, they sometimes migrate, forming relatively inactive clumps.

To make this new liquid catalyst that resists clumping, Shi Bai of the University of Delaware, Z. Conrad Zhang of Dalian Institute of Chemical Physics, and coworkers reacted a platinum salt with alcohols in a solution of poly(dimethylsiloxane)-poly(ethylene glycol) (PDMS-PEG). The reaction yielded a catalytic liquid composed of isolated platinum atoms that resist aggregating due to their interactions with hydrochloride species and oxygen atoms in the PDMS and PEG ligands. Tests of the catalyst in hydrosilylation reactions, used by the silicone industry to make carbon-silicon bonds, showed the new material was stable, reusable, and 100 times as active as common platinum catalysts.

Catalysis specialist Daniel E. Resasco of the University of Oklahoma thinks that the highlight of the work is that the team chose ligands that bind to the metal atoms strongly enough to prevent them from forming nanoparticles, but weakly enough to allow for high catalytic activity. Resasco notes that this weak interaction hardly alters the metal’s electronic state, leaving the active sites “pristine,” ideal for researchers conducting fundamental studies to deduce reaction mechanism.

Bert M. Weckhuysen of Utrecht University, an expert in analyzing catalysts, points out that because the catalyst is a liquid, chemists can use many spectroscopy methods and characterization techniques to analyze it and uncover mechanistic insights.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter