Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Catalysis

New method makes starch from CO₂ faster than plants can

The advance hints at sustainable, efficient factory production of food and industrial chemicals

by Prachi Patel, special to C&EN

September 24, 2021

Feeding the world uses enormous amounts of land, water, fertilizer, pesticide, and fuel. In a step towards a more sustainable solution, researchers have designed a method to make starches from carbon dioxide more efficiently than plants do (Science 2021, DOI: 10.1126/science.abh4049).

The new technique, which relies on chemical catalysts and a curated combination of natural and engineered enzymes, converts CO2 to starch 8.5 times as efficiently as corn plants can.

“This suggests that it is possible we can produce starch in a factory rather than on a farm, which should be a way to ensure human food security and reduce carbon dioxide emissions,” says Yanhe Ma, a microbiologist at the Tianjin Institute of Industrial Biotechnology. The synthetic starch could find industrial use and as an ingredient in animal or human food.

Starches, a form of carbohydrates, are a major source of food calories, and we rely on plants to produce them. But the process is complex and inefficient. Speeding up photosynthesis in plants or artificially making starch have been challenging. Researchers have been able to make starch from plant-derived cellulose or from sucrose by using enzymes, but not yet from CO2.

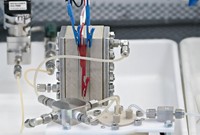

To use CO2, Ma and his colleagues use a zinc- and zirconium-based catalyst to reduce CO2 to methanol, which serves as the building block for the rest of the process. They use enzymes to turn the methanol into three-carbon sugar molecules. And then again using enzymes, they polymerize those sugars into six-C sugars, and finally into long-chain starch molecules.

The process involves 11 core reactions and originally took 10 h, the researchers report. To speed it up, they systematically studied the efficiency of each step. They identified bottlenecks caused by natural enzymes, and made better enzyme variants with the help of computational design. This was key to making the process more efficient, leading to a final run time of 4 h, says Ma. Corn plants require 120 days to make starch. The new technique converts CO2 into starch at a rate of 22 nanomoles per min, 8.5 times as efficiently as corn.

Converting CO2 to methanol is energy-intensive because it requires high temperature and pressure. But the researchers calculate that if they use solar energy for electricity and to produce hydrogen from water electrolysis, the new artificial process converts solar energy to starch 3.5 times more efficiently than plants.

“This is a very nice example of how to interface chemistry and biology, combining the best of both worlds,” says Tobias Erb, a microbiologist at the Max Planck Institute for Terrestrial Microbiology.

James Bowie, a biochemist at the University of California Los Angeles, says that an upside of this creative approach is that along the path to making starch, it gives other useful chemicals and biofuels. It is a long way from being practically relevant, though; one key hurdle is making stable enzymes on a large scale at low cost. Another is designing and building the right reactor. “Those problems are mostly technical and solvable,” Bowie says.

Ma says his team is working on improvements. Plenty of room remains to increase the efficiency and productivity of the technique, he says. “Next, we will focus on increasing the activity and stability of the enzymes we used to significantly decrease the cost for artificial starch synthesis.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter