Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Catalysis

Watching vanadium catalysts dehydrogenate propane

Vanadium-bound hydroxyl groups promote reaction and ward off harmful carbon buildup

by Mitch Jacoby

April 12, 2018

| A version of this story appeared in

Volume 96, Issue 16

Produced at the multi-million-metric-ton level, propylene ranks as one of the main building blocks in petrochemistry. Refineries produce the light olefin, which is then converted to polypropylene and other compounds, primarily by cracking naphtha and other petroleum starting materials.

Low-cost supplies of propane from shale gas have prompted some manufacturers to make propylene, instead, via propane dehydrogenation (PDH), a process commonly mediated by platinum and chromium catalysts. Vanadium-based catalysts, which would bypass the high cost and toxicity concerns associated with the other metals, look like promising alternatives. But mechanistic details of vanadium PDH catalysts remain unknown, limiting scientists’ ability to improve them.

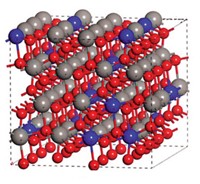

To address that shortcoming, a research team led by Jinlong Gong of Tianjin University prepared alumina-supported vanadium oxide catalysts and probed their PDH activity with vibrational spectroscopy, computations, and other methods.

The team found that pretreating the catalysts with hydrogen forms V-OH groups, which promote the PDH reaction and improve catalyst stability. They also found that V3+ surface sites demonstrate more PDH activity than V4+ and V5+ sites. Omitting the hydrogen pretreatment and exposing the catalysts directly to propane forms the active V3+ sites without the OH caps. This OH-less form of the catalyst shows high PDH activity initially, but it quickly becomes inactive because of a buildup of carbon gunk called coke, which blocks catalyst sites (Angew. Chem. Int. Ed. 2018, DOI: 10.1002/anie.201800123).

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter