Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Fuel Cells Minus Membranes

Laminar flow in microfluidic channel prevents fuel and oxidizer from mixing

by Mitch Jacoby

March 29, 2004

| A version of this story appeared in

Volume 82, Issue 13

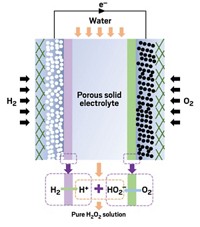

A key component of common fuel cells—the membrane that isolates the fuel from the oxidizer—has been eliminated in a new fuel-cell design that uses microfluidic effects to separate the reagents. The design simplifies the electrochemical devices and may lead to new types of fuel cells that are free from the problems that typically bedevil membrane-based power systems.

The membrane that is found in polymer electrolyte membrane (PEM) fuel cells serves as a barrier to prevent the fuel and oxidizer from mixing without generating electricity. Ideally, electrons and protons from a fuel are liberated at a catalyst-coated anode and travel via separate routes to a cathode where they react with an oxidizer. Protons migrate through an electrolyte medium—the membrane—while electrons travel through an external circuit to provide electrical power.

Much of the research on PEM cells focuses on improving the membrane to improve overall cell performance. For example, scientists are trying to find robust substitutes for the commonly used membranes that can tolerate temperatures higher than about 80 °C, the temperature at which PEM cells are typically operated. Raising the temperature would speed up reaction kinetics but may dehydrate the membrane, which would reduce proton conduction and cell performance. Fuel permeating through the membrane is another problem.

Now, researchers at the University of Illinois, Urbana-Champaign, have sidestepped these issues by devising a fuel cell that omits the membrane. By pumping aqueous fuel and oxidizer solutions through a micrometer-sized Y-shaped channel, the group induces laminar flow in which the reagents proceed along the length of the channel in parallel streams with no mixing except for a small amount of diffusion that's controlled by the channel dimensions and flow rates [J. Power Sources, 128, 54 (2004)].

The team, which includes graduate student Eric R. Choban, assistant chemical engineering professor Paul J. A. Kenis, and their coworkers, uses standard techniques to prepare the channels in polymeric materials. And they use electrodeposition methods to form platinum-black electrodes along the length of the channel on opposite walls.

Kenis points out that, unlike related work by other research groups in which inorganic compounds react in a redox cell to generate electrical current, the microfluidic system uses readily available reagents including methanol, formic acid, potassium permanganate, and oxygen.

In the prototype

fuel cell's current form, fuel efficiency is low, Kenis acknowledges. One approach to improving performance is to include additional channel outlets to remove small amounts of depleted reagents, thus allowing unused solutions to reach the electrodes. The group also is experimenting with a design in which a recirculating electrolyte stream flows between the fuel and oxidizer and is "spiked" regularly with small amounts of fresh fuel.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter