Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Soup-to-nuts DNA Analysis

Sample preparation, amplification, and detection on a single microfluidic device

by CELIA M. HENRY

April 5, 2004

| A version of this story appeared in

Volume 82, Issue 14

BIOCHIPS

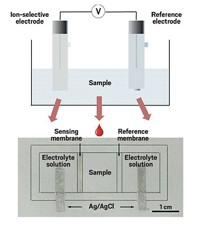

A new microfluidic device takes DNA analysis from start to finish in a single, inexpensive, integrated system, a team of industry and academic scientists report. Sample preparation, polymerase chain reaction, DNA hybridization, and electrochemical detection are all performed in a miniature 60- × 100- 2 ×-mm plastic device [Anal. Chem., 76, 1824 (2004)].

“We attempt the most challenging problems people are facing in microfluidic applications, which is on-chip sample preparation integrated with back-end DNA detection,” says lead author Robin H. Liu of CombiMatrix, in Seattle. “Due to the complexity of the sample preparations, most available biochip systems perform the initial step off-chip using traditional benchtop methods.” The development work was done at Motorola Labs, in Tempe, Ariz.

“Cost is definitely the number one concern for industry,” Liu says. “All the materials and technology we consider must be low cost. If you look at the whole device, which consists of micropumps, valves, mixers, temperature sensors, integrated heaters, the Motorola eSensor, and all the fluid channels, it has a total manufacturing cost of only $7.00 per device.”

All the components that are integrated in the device are “simple yet functional and robust,” Liu says. For example, in the device’s paraffin-based microvalves, a plug of wax and a heater on a printed circuit board are used to control fluid flow. “We actually used birthday candles to make the valves,” Liu says. Unlike other technologies, no diaphragms or external air sources are needed to control the valves.

Nor does the device require an external pressure source to drive fluid flow. “We have two micropump mechanisms,” Liu says. “One is a thermopneumatic pump, which is simply air pockets attached to a heater.” The other pump uses the electrolysis of water to generate gases that push liquids through the system. “These pumping mechanisms are extremely simple. I don’t see any technology available right now simpler than this.”

Liu believes that the device will be useful in a number of applications. “This device provides a cost-effective solution to direct sample-to-answer genetic analysis,” Liu says. “It has a potential impact in the field of point-of-care genetic analysis, environmental testing, biological warfare agent detection, and so forth.”

Andreas Manz, head of the Institute of Spectrochemistry & Applied Spectroscopy, in Dortmund, Germany, and one of the pioneers of micro total analysis systems (TAS), says: “This paper is really good experimental evidence that a micro TAS can be designed and put together, and it really works.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter