Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Nanoreduction Of Graphene Oxide

Materials: Scanning probe method patterns insulator with conducting features

by Mitch Jacoby

June 14, 2010

| A version of this story appeared in

Volume 88, Issue 24

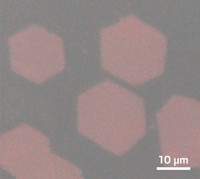

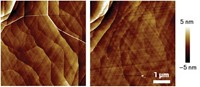

Graphene oxide, an oxidized form of the advanced carbon material graphene, can be controllably reduced by passing a heated atomic force microscope (AFM) tip over the material, according to a report published in Science by an international team of researchers (2010, 328, 1373). The procedure provides a way to pattern the relatively easy-to-prepare nonconducting material with nanosized conducting lines and other features—an advance that may hasten its implementation in nanoscale circuitry.

Graphene’s outstanding electrical conductivity and mechanical strength have made this atomically thin form of carbon a much-studied material for nanoscale electronics applications. Graphene oxide, which can be prepared readily via the 150-year-old technique of treating bulk graphite with strong oxidizers, is sometimes used as a starting material for making sheets of graphene. The oxidized material, which contains hydroxyl, epoxide, and carbonyl groups, can be treated with potent reducing agents such as hydrazine or heated strongly (to 1,100 °C in some procedures) to yield graphene.

Now, Paul E. Sheehan, a chemist at the Naval Research Laboratory in Washington, D.C.; physicist Elisa Riedo of Georgia Institute of Technology; and coworkers in the U.S., South Korea, and France have shown that by using a heated AFM tip, they can selectively reduce regions of graphene oxide as narrow as 12 nm and can control the extent of reduction and thereby customize the reduced regions’ electronic properties. The reduced sections, which differ from pristine graphene in that they contain residual oxygen and various structural defects, are up to 10,000 times more electrically conductive than the surrounding regions, the team says. They add that the reduction process can be automated by using arrays of independently controlled probe tips.

Northwestern University graphene specialist Jiaxing Huang notes that the procedure may enable graphene circuits to be “written” directly on graphene oxide sheets. He adds that further study is needed, however, to ensure that the graphene oxide matrix remains oxidized and does not spontaneously, if slowly, undergo reduction and cause short circuiting.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter