Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Finding Green In Gold

Materials: Precious metal in nanostructured form mediates oxidations selectively

by Mitch Jacoby

January 18, 2010

| A version of this story appeared in

Volume 88, Issue 3

A novel nanoporous gold material prepared by removing silver from a gold-silver alloy selectively catalyzes production of an industrially important compound under mild conditions, according to a team of researchers in Germany and the U.S. (Science 2010, 327, 319). The study further broadens gold’s rapidly growing repertoire of catalytic reactions. It also could help efforts to replace industrial chemical processes with less hazardous and “greener” ones.

In just the past few years, gold’s reputation as an inert noncatalytic metal has undergone a complete makeover, as several research groups have found a number of reactions—including various types of oxidations—that are catalyzed by gold in nanostructured form. Nonetheless, commercial applications have been impeded by gold’s slowness to dissociate oxygen—a key step in oxidations—and the tendency of nanoparticles to agglomerate under typical reaction conditions. That process quickly shortens the lifetimes of supported catalysts such as gold, which is usually dispersed on the surfaces of solid oxides.

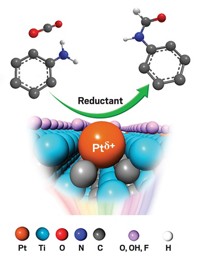

The new catalyst may provide a way around those problems. By treating a gold-silver alloy with nitric acid, the researchers formed a stable, unsupported monolithic gold catalyst composed of a three-dimensional network of nanoscale ligaments. The team, which includes Arne Wittstock, Volkmar Zielasek, and Marcus Bäumer of Bremen University, in Germany; Harvard University’s Cynthia M. Friend; and coworkers, found that at low temperature and 1 atm of oxygen, the nanoporous material catalyzes oxidative coupling of methanol to yield methyl formate. That compound is used commercially as a solvent and blowing agent and as a precursor to formic acid and dimethylformamide. It is prepared industrially in a process that uses carbon monoxide, methanol, caustic base, and metallic sodium.

At room temperature, the gold-catalyzed reaction is 100% selective but runs sluggishly, the team reports. Raising the temperature to just 80 °C speeds up the reaction, increases methanol conversion several-fold, and only slightly reduces selectivity—producing about 3% CO2, according to the researchers. They note that the catalyst remained stable and active during tests that ran continuously for periods ranging from days to weeks. In addition, on the basis of experiments comparing a series of de-alloyed samples, the team concludes that a small fraction of residual silver enhances the gold catalyst’s reactivity by promoting oxygen dissociation.

“It is tempting to assume” that results from this type of gold catalyst with residual silver may be better than those from pure gold catalysts used before in oxidation reactions, Claus H. Christensen of Danish catalyst manufacturer Haldor Topsøe and Jens K. Nørskov of the Technical University of Denmark note in a commentary about the work. Further research is needed, but this advance may move green gold catalysis closer to industrial applications, they say.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter