Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

2-D Materials

Graphene Helps A Robot Creep Like An Inchworm

Device Materials: Strong, speedy actuators made from graphene could move robotic parts and medical devices

by Katherine Bourzac

April 27, 2012

Whether building robots that move like insects or fish, or designing medical implants with moving parts, researchers look for new materials that respond to electricity but are flexible and soft. To meet that need, Chinese scientists have developed graphene-based actuators that convert electricity into motion (ACS Nano, DOI: 10.1021/nn3006812).

In robots, actuators act like muscles, driving the movement of mechanical arms and fins. Most electromechanical actuator materials, such as ceramics and conductive polymers, respond slowly, require a lot of power, or provide very little force.

To make speedy, strong actuators, Nankai University researchers led by Yongsheng Chen and Yi Huang coated graphene paper with the polymer polydiacetylene. Other researchers had shown that polydiacetylene deforms in response to electrical current. But alone, it’s not a good actuator material, because it’s brittle. Graphene provides a highly conductive, flexible backing for the fragile crystal.

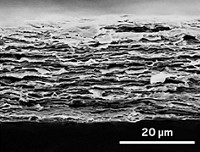

To make the graphene paper, the scientists filter graphene flakes to create a sheet, and then heat them to fuse them together. They then spin-coat the paper with a solution of the monomers needed to make polydiacetylene. Hitting the sheets with ultraviolet light cures the polymer, making a crystalline layer of the material.

The researchers can cut the actuator sheet into any shape they want and then wire it to an electrical source. Depending on the type of applied electrical current, a strip of the material moves in different ways. In response to an alternating current, the material swings back and forth, matching the current’s frequency. The material’s response is rapid: A 200-Hz alternating current, for example, causes the device to swing 200 times per second. Chen says the team is trying to understand how this material responds so quickly to current.

When the scientists apply low levels of direct current, the material generates as much stress as natural muscle can. It can produce 160 megapascals of stress per gram of material, making it stronger than most polymers.

The team also made a simple inchworm robot from a sheet of this material. As they supplied different levels of electrical current, the robot arches and relaxes to crawl forward, slowly but surely: It moved about 5 mm in 20 seconds. “We believe it can move much faster with a little design optimization,” says Chen.

Kwang Kim, of the University of Nevada, Reno, says the fast response time of the actuator material is promising for mimicking natural movement in robots. “Muscle is very soft, and responds to a request on demand,” he says. For example, he says, muscles in the fingers contract to avoid dropping a glass before a person is even aware that it is slipping.

Chen is working on refining the graphene actuators. With Ray Baughman, a materials scientist at University of Texas, Dallas, he’s working to find an easier-to-process replacement for polydiacetylene. And he’s working on making more devices, including a bee-sized helicopter-style robot that would use the actuators to spin the blades.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter