Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Water-Driven Micromotors Rocket Around

Nanodevices: Particles that use water instead of hydrogen peroxide as fuel could find use in biosensor devices

by Sarah Webb

August 27, 2012

Over the past several years, bioengineers have built micro- and nanosized rockets that zip through liquids, fueled by chemical reactions between the materials that make up the rockets and their environments. The engineers hope someday these tiny motors could help deliver cargo, such as drugs. Unfortunately, many of these motors require toxic hydrogen peroxide as fuel source, limiting their use in the body. Now researchers have overcome this constraint by developing micromotors that run on water (ACS Nano, DOI: 10.1021/nn303309z).

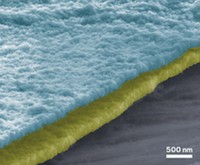

The particles, which are 20 µm in diameter, are asymmetric: A chemical reaction on the back side of the particle forms gas bubbles that propel the motor forward. The micromotors harness a well-known reaction between aluminum and water to produce hydrogen gas and aluminum hydroxide.

Joseph Wang of the University of California, San Diego, and his team made the particles out of an aluminum-gallium alloy. The gallium prevents a film of aluminum hydroxide from forming on the particle during the reaction. Without gallium, the film would stop the reaction by coating the aluminum surface, says Wang.

To make the motors, the researchers added liquid gallium to aluminum particles to form the alloy. They then coated one side of the particle with titanium, making that face inert while the other face remained reactive in water.

They found that their motors can dash off at a speed of 3 mm per second in water. In other aqueous solutions, such as salt solutions, cell growth media, and human blood serum, the particles move more slowly.

Wang cautions that applications, such as drug delivery, are a long way off. One of the hurdles he must leap is that his motors don’t last long because the reaction isn’t catalytic. As the aluminum reacts with water, the particles dissolve after about a minute. In salt solutions, the slower reaction increases the lifetime to almost five minutes. Wang says his team is investigating other alloys and reactions that could last longer.

Other materials and alloys might solve another problem: toxicity. As the water-fueled particles break down, they release aluminum and gallium, which could harm cells. Zinc is a less toxic motor material. Wang and his colleagues recently reported motors made with zinc that use acid as fuel (J. Am. Chem. Soc., DOI: 10.1021/ja210874s).

Despite their limitations, the water-fueled motors tackle a major problem bioengineers have been struggling to solve, says Samuel Sanchez of the Leibniz Institute for Solid State and Materials Research, in Dresden, Germany. He thinks researchers could use the motors in biosensor devices that require transporting DNA or cells.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter