Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Chemists Get Back To The Grind With Mechanochemistry

Force provides ways to run reactions in ball mills with little or no solvent

by Jyllian Kemsley

January 14, 2013

| A version of this story appeared in

Volume 91, Issue 2

Grinding a compound to create a new one dates back to at least 315 B.C. That’s when Aristotle’s student Theophrastus of Eresus wrote about the reduction of cinnabar—mercury(II) sulfide—to elemental mercury by grinding it with a copper mortar and pestle, according to Laszlo Takacs, a physics professor at the University of Maryland, Baltimore County, and an expert on the history of mechanochemistry. Scientific publications from the 1880s to the early 1900s indicate that chemists used a mortar and pestle to induce chemical reactions, such as an 1893 preparation of halogen derivatives of quinhydrone (J. Chem. Soc., Trans., DOI: 10.1039/ct8936301314).

The idea of grinding as a means for chemical reactions then seemed to fall out of favor. Chemical synthesis largely became the domain of flasks and solvents.

In the past several years, however, the approach has reemerged—albeit often through the use of a ball mill rather than a mortar and pestle—and it is proving itself to be a quick and convenient way to make some organic and inorganic materials with minimal solvent use and waste.

It’s a field ripe for experimentalists, says Tomislav Friščić, a chemistry professor at Montreal’s McGill University who explores milling metal oxides to produce metal-organic frameworks (MOFs) and metallodrugs. “Whatever you do really is something that hasn’t been done before,” Friščić says.

“As chemists, we’re willing to try crazy things, and out of crazy comes really interesting chemistry,” adds Richard G. Blair, a chemistry professor at the University of Central Florida who is working on milling cellulose to break it down into sugars or smaller organic compounds.

Chemistry via milling falls under the umbrella term mechanochemistry, which also includes the use of single-molecule techniques to tug on individual bonds or the use of ultrasound to put stress or strain on molecules to induce reactions (C&EN, Oct. 1, 2012, page 55). Mechanochemical milling generally involves standard industrial ball mills, which shake, tumble, or stir hard balls to grind whatever other material is added. Mills handle amounts from less than a gram to tons at industrial scales. Reactions may use no solvent or just a few drops. When the balls collide in the mill, several processes play a role in the reactions that ensue, including shear stress, increased pressure, and increased temperature.

Running a reaction in a ball mill is generally as simple as tossing in a couple of compounds, turning on the mill, and letting it go, says Jonathan W. Steed, a chemistry professor at Durham University, in England. Over the past decade, Steed says, mechanochemistry has “just sort of seeped into what we do day by day,” to make materials for supramolecular synthesis.

A 2011 review listing examples of inorganic reactions done mechanochemically includes the formation of oxides, halides, sulfides, nitrides, and composites (Chem. Soc. Rev., DOI: 10.1039/c1cs15171a). On the organic side, mechanochemical milling can accomplish asymmetric anhydride openings, aldol formations, alkylations, Michael additions, and metal-organic reactions, often with less catalyst and in less time than solution synthesis. Products may still require purification, so the approach may not eliminate solvents entirely, but practitioners say it allows them to reduce how much they use and often lets them choose less hazardous liquids than they would need for solution synthesis.

“Sometimes it works and sometimes it doesn’t,” Steed says, but when it does, the ease and lack of waste make a mechanochemical synthesis very attractive.

Work under way at Barry University showcases the technique’s simplicity. Chemistry professor Tamara Hamilton uses it to make porphyrins, with the eventual goal of trapping reagents inside catalytic metal-organic polyhedra. So far she’s been able to replace the first step of solvent-based porphyrin synthesis with a mechanochemical approach that produces the same yield in 20 minutes. The traditional synthesis requires a couple of hours, anaerobic techniques, and chlorinated or propionic acid solvents.

Despite these advantages, much of mechanochemical synthesis is a black box, researchers who use the approach agree. The architecture of ball mills makes it impossible to watch reactions in real time to follow intermediates and develop a better understanding of reaction mechanisms and which parameters might affect them.

Consequently, mechanochemistry is “sort of voodoo witchcraft,” says James Mack, a chemistry professor at the University of Cincinnati. He is one researcher trying to dig deeper into mechanochemistry to provide a more methodological understanding. Mack has experimented with different types of materials for mill vials and balls, including stainless steel, nickel, and polytetrafluoroethylene, which DuPont brands as Teflon. “The hardness of the vial will impart different energy, so you get different yields or types of reactions,” Mack says. The number and size of balls also affect reactions.

Removing solvation effects in going from solution synthesis to milling can make a big difference in how reactions happen, Mack says. Reactions wind up being more like reagents “swapping partners” than going through separate, charged intermediates.

And in some cases, adding even small amounts of liquid can make a big difference. One project in Mack’s lab involves ball-milling resins to crack them and expose functional interiors, rather than swelling them in benzene, toluene, or dichloromethane. Last year, he reported that solvent can determine product stereochemistry when milling triphenylphosphine-functionalized polystyrene to produce alkenes through Wittig reactions. No solvent or a few drops of ethyl acetate, n-hexane, or toluene produced E isomers, whereas dichloromethane, ethanol, or isopropanol produced Z isomers (Green Chem., DOI: 10.1039/c2gc35669d).

Last year also saw McGill’s Friščić report a way to use in situ powder X-ray diffraction to image mixtures in operating milling reactors (Nat. Chem., DOI: 10.1038/nchem.1505; C&EN, Dec. 3, 2012, page 32). Friščić uses a synchrotron source that produces a beam strong enough to penetrate milling vials made of steel, aluminum, or polymethyl methacrylate. The technique should allow scientists to probe what’s going on in mills in real time.

Researchers are not using mechanochemistry at just the laboratory scale but are also eyeing ways that it might improve industrial processes. MOFs are one example. Touted for their potential use in applications such as gas storage or separations, they’ve been hampered by the need for an inexpensive, large-scale synthesis, says Stuart L. James of Queen’s University Belfast. He thinks mechanochemical synthesis can fill that need and has founded a company, MOF Technologies, to develop his approach.

Another area that may be on the horizon for industrial-scale mechanochemistry is the production of biofuels through degradation of lignin or cellulose. Carsten Bolm, a chemistry professor at Germany’s RWTH Aachen University, recently degraded lignin model compounds as well as lignin extracts and dried beechwood by grinding the different materials with solid sodium hydroxide for several hours (Green Chem., DOI: 10.1039/c2gc36456e). On the cellulose front, Central Florida’s Blair is working with cellulosic sugar manufacturer Carbolosic to scale up a method for grinding cellulose with clays to break down the material to sugar, which he reported in 2010 (Green Chem., DOI: 10.1039/b923079c). He’s also investigating ways to split the sugar into three-carbon compounds that are more useful as potential feedstocks.

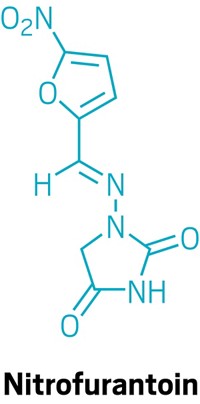

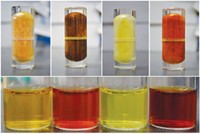

But the area where mechanochemical milling is perhaps making the quickest inroads into industry is in pharmaceuticals, where creating cocrystalline forms of an active pharmaceutical ingredient with other compounds can change their solubility and bioavailability. A cocrystal is a hybrid or composite phase in which two or more molecules exist in a new crystalline form in a stoichiometric ratio, says Michael J. Zaworotko, a chemistry professor at the University of South Florida. The components interact through weak forces such as hydrogen bonds, π-stacking, or charge-transfer interactions.

And milling provides “a very quick, convenient, green, and cheap way to screen for new compositions,” Zaworotko says. Many cocrystalline forms may even be impossible to produce using traditional solvent-based evaporation, he adds, because usually the least soluble component will be isolated rather than the cocrystal form. But “you can grind together two perfectly happy crystalline solids and make an even happier cocrystalline material” in five minutes with 95 to 100% purity, Zaworotko says, defining “happy” as thermodynamically stable.

Mechanochemistry will probably not displace solution synthesis, but it’s a useful tool for the chemist’s tool kit, practitioners say. “It’s extremely environmentally friendly and efficient, and that can only be a good thing in terms of chemistry’s impact on the world,” Steed says. “It’s a simple idea but represents a paradigm shift in the way chemists think.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter