Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Measuring Oil’s Asphaltenes

Analytical Chemistry: A novel microfluidic chip quantifies the sticky fraction of crude oil that can gum up oil exploration

by Louisa Dalton

April 30, 2013

The blackness of crude oil comes from a dark, sticky fraction of compounds that make purifying petroleum tricky. To make purification easier, oil companies measure the concentration of these tarlike, polar molecules called asphaltenes, a process that can take two days. A new microfluidic chip can make the asphaltene measurements in less than an hour, researchers report (Anal. Chem., DOI: 10.1021/ac400495x).

Asphaltenes have little value as fuel—they usually end up used for pavement—yet they cause some of the biggest headaches for the oil industry. The little understood aromatic compounds solidify easily in response to environmental changes. The sticky solids clog exploratory pipelines or production conduits. In worst-case scenarios, the asphaltenes plug up the rocky underground channels of oil reservoirs, shutting down the oil well.

In their efforts to avoid clogging and high costs, oil companies measure asphaltene concentration whenever possible. These measurements help them determine the oil quality in a reservoir and how much processing a crude oil will need. They send a sample to a laboratory where a technician uses a beaker-full of solvent to precipitate and filter the asphaltene fraction. After dissolving the sticky substance, the technician then cleans, dries, and carefully weighs it. The whole process takes about two days.

“It’s a difficult measurement to take,” says Farshid Mostowfi at Schlumberger, an oil services company. Because the steps are laborious, people don’t run the test as often as they like, he says.

For the past seven years, Mostowfi has been miniaturizing wet chemistry tests in the oil industry using microfluidics. When he approached the asphaltene test, he knew he couldn’t simply miniaturize the current lab process: He couldn’t replicate the drying and weighing steps in a microfluidic chamber.

So Mostowfi and his group first found a way to quantify asphaltenes without weighing them. The group took an optical spectrum of diluted crude oil, precipitated and filtered the asphaltenes, and then took another spectrum of the leftover oil (Energy Fuels, DOI: 10.1021/ef400050y).

By measuring the oil’s spectra before and after asphaltenes, Mostowfi’s group got an indirect reading of asphaltene content that was more precise than the traditional weight method.

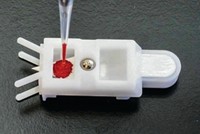

With this optical technique in hand, Mostowfi and colleagues have now miniaturized the process. They worked with a U.K. company, Dolomite, to make a 25- by 25-mm glass microfluidic chip. After a researcher pumps an oil sample into the chip, the system automatically dilutes it and optically measures the whole oil with an ultraviolet-visible spectrophotometer. The system then adds heptane to precipitate the asphaltenes, filters the oil, and takes another optical spectrum.

Precipitating solid particles in microchannels without clogging the channels was a bit of a design challenge, Mostowfi admits. They managed it by monitoring the pressure at the filter where clogging is most likely to occur, and cleaning the channels. One chip lasts for several months. With this new device, the measurement of asphaltenes in crude-oil samples took about 40 minutes and requires only a few milliliters of solvent.

Win Robbins, an oil consultant at Carmagen Engineering, says the optical method underlying Mostowfi’s chip “will be of interest to the oil industry” once it has been tested on more samples from around the world. He points out that the optical measurements can be performed fairly easily in the lab without the need for microfluidics.

Mostowfi agrees yet says the chip automates the process so anyone can run it. It also cuts down on the necessary time, sample size, and solvent volumes compared to the laboratory version. A quick, portable test, he adds, can be performed more often in the field, leading to more informed exploration, better quality control in production, and better prediction of asphaltene precipitation.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter