Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Coatings

Titanium Dioxide Coating Improves Efficiency Of Graphene-Based Solar Cells

Solar Energy: The antireflective layer could lead to efficient, low-cost devices

by Prachi Patel

April 3, 2013

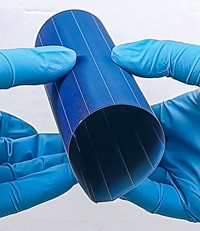

Adding a layer of graphene to silicon solar cells cuts the devices’ potential costs. Such graphene-silicon cells, though, convert light to electricity with low efficiencies. A team of researchers now has boosted this efficiency by giving the solar cells an antireflective veneer (Nano Lett., DOI: 10.1021/nl400353f).

Commercially available silicon solar cells convert about 15% of incoming light energy into electrical energy. But the cells are expensive to fabricate in part because of the costs of adding a thin, charge-carrying silicon layer on top, a process that requires high temperatures. The devices are also capped with a grid of thin silver wires that serve as an electrode.

Researchers led by Anyuan Cao of Peking University, in China, recently found that a graphene film can replace this charge-carrying layer, as well as serve as electrodes for the devices. Creating such films is a relatively inexpensive process. However, those graphene-silicon devices have efficiencies that top out around 8.6%, less than the 10% considered viable for commercial cells.

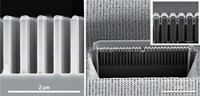

So Cao and his colleagues, including Hongbian Li of the National Center for Nanoscience and Technology, in Beijing, and Hongwei Zhu, of Tsinghua University, turned to an old trick used to improve the efficiency of silicon solar cells. They coated the graphene-silicon structure with a 65-nm-thick layer of titanium dioxide. This coating decreased the amount of visible light reflected from the silicon surface from over 30% to less than 10%. Less reflected light meant the device absorbed more light to convert to electricity, and the efficiency of the cells jumped to 14.6%.

The researchers currently grow the graphene layer on copper foil using chemical vapor deposition, which requires relatively high temperatures, and then transfer it to the top of a silicon wafer. Cao points out that they could further lower costs for the cells by painting or spaying a graphene solution onto the silicon wafers to produce the graphene film.

The graphene-silicon cells are several square millimeters in area. To be more practical, the devices need to be larger, Cao says, which presents another hurdle his team must face. As the area of a graphene film increases, so does its resistance, making the solar cells less efficient.

The researchers also need to make the devices more stable, says Yongsheng Chen, a chemistry professor at Nankai University, in China: The device efficiency drops after sitting in the air for 20 days. Nevertheless, he says that the work is significant for its use of two abundant materials—silicon and graphene—to make solar cells without the need for high-temperature processing. “This, combined with the high power-conversion efficiency, makes it potentially attractive for next-generation solar cell technology.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter